Emerson provides robust process control and safety solutions across hydrogen production, compression, and storage systems. Its DeltaV™ Distributed Control System (DCS) and Rosemount™ smart sensors are widely deployed in green hydrogen plants. In a renewable hydrogen demonstration plant in California, Emerson supplied a complete DCS and Safety Instrumented System (SIS) for real-time monitoring of temperature, pressure, and flow parameters. Integrated with AMS Device Manager, the system enables predictive maintenance and alarm management, reducing operational failure rates by 20%.

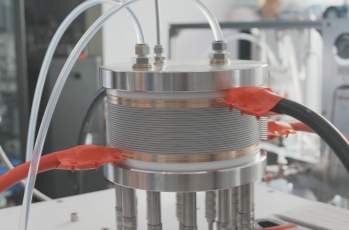

Furthermore, Fisher™ control valves and Micro Motion™ Coriolis flowmeters are extensively used for hydrogen flow regulation and storage management, ensuring precision and safety under high-pressure conditions. Emerson’s technologies deliver both reliability and compliance with international safety standards for hydrogen systems.