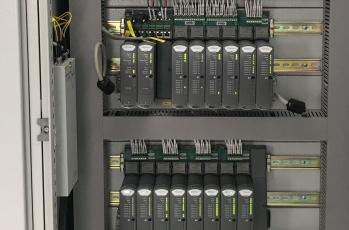

Honeywell offers comprehensive automation solutions that integrate distributed control systems (DCS), safety instrumented systems (SIS), and advanced optimization tools.

In refineries, Honeywell Experion systems manage distillation columns, catalytic cracking units, and blending processes, achieving higher throughput while ensuring consistent product quality. In liquefied natural gas (LNG) plants, Honeywell automation systems integrate cryogenic process control with safety systems to ensure stable operation under extreme temperatures and pressures. These integrated solutions help operators reduce energy consumption while meeting stringent safety standards.