-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

As a field engineer who spends more time in control rooms and marshal cabinets than in conference rooms, I see the same pattern in plants with aging distributed control systems: the equipment still runs, but your risk, support exposure, and missed capability compound every year. This is particularly acute for Honeywell TDC 3000 and Yokogawa CENTUM sites that must keep throughput and safety intact while they modernize. In this article, I distill practical modernization paths, decision tradeŌĆæoffs, and onŌĆæsite lessons learned. Where specific source knowledge exists, I cite the publisher; where I infer from crossŌĆævendor best practice and handsŌĆæon experience, I say so and note confidence.

Even if your legacy DCS appears stable, the business case is usually hiding in plain sight. Obsolescence and parts scarcity raise mean time to repair; OS and firmware age widen your cyber attack surface; and the lack of modern data, alarm, and APC capabilities quietly taxes yield and energy. Industry commentary has repeatedly highlighted the economics of unplanned downtime, which often ranges from about $125,000.00 to several million dollars per hour depending on sector and unit criticality, making resilience and disciplined patch practice financially decisive (LinkedIn). On the Honeywell side, there is a concrete date to plan around. Industrial Design Solutions has communicated a phaseŌĆæout for Honeywell coax subsystems and stated that support for TDC 3000 reaches its end on December 31, 2025. Treat that as a hard planning anchor and work backward.

TDC 3000 integrated operator stations, controllers and I/O over the Local Control Network and the Universal Control Network. Archival technical material on the Advanced Process Manager indicates UCN used a 5 Mbps token bus and was introduced to users in 1988, with serial integrations to Modbus and AllenŌĆæBradley subsystems reaching out into brownfield islands (Scribd). In practical plant terms, TDC 3000ŌĆÖs longevity is a doubleŌĆæedged sword. The installed base is vast, you can still keep a surprising amount of it alive, and HoneywellŌĆÖs modernization programs explicitly preserve graphics, logic, controllers, I/O processors and wiring to protect intellectual property and minimize ripŌĆæandŌĆæreplace (Honeywell Process Solutions). At the same time, coax and aging platform dependencies drive up support and cyber risk; the December 31, 2025 milestone means ŌĆ£laterŌĆØ is no longer an option.

The CENTUM family has been a mainstay DCS for decades with deep penetration in process industries. While our research notes did not contain a vendorŌĆæauthored CENTUM modernization brief, the platformŌĆÖs reputation and my field exposure suggest a modernization posture that favors incremental migration, operator HMI continuity, and lifecycle planning consistent with broader DCS best practice. Where I discuss CENTUM below, I am extrapolating from crossŌĆævendor methods and project experience rather than citing productŌĆæspecific features; confidence for those inferences is medium.

Aging DCS modernization is not a single decision; it is a set of interlocking choices that determine risk, downtime, and ROI. IEB Media frames four decisions that consistently show up in winning projects. The first is whether you replicate likeŌĆæforŌĆælike or innovate. Replication swaps hardware with minimum functional change, which can cut immediate risk and costs. Innovation uses the transition to adopt smarter I/O, highŌĆæperformance control, and redesigned HMIs that reduce operator cognitive load, usually delivering better lifecycle returns. The second choice is horizontal versus vertical scope. Horizontal replaces like equipment across units first, such as HMI across all boilers, while vertical replaces an entire slice from HMI to I/O in one area. The third is ripŌĆæandŌĆæreplace versus phased migration; the former compresses execution but concentrates downtime, whereas the latter sequences HMI, controllers, and finally I/O to spread risk and outage windows. The fourth is hot versus cold cutover. Hot cutover runs legacy and new in parallel and transfers loops one by one, significantly reducing downtime and risk at the expense of space and complexity; cold cutover replaces en masse during a full shutdown. Plants that optimize total cost of operations, not just project cost, tend to choose innovation, phased migration, and hot cutover, backed by rigorous simulation.

Your justification should start with a risk register and a credible value stack. Obsolescence and support exposure are immediate. Cybersecurity debt from older Windows and embedded stacks demands segmentation, patch governance, and secure remote access. Workforce considerations are real: experienced DCS technicians retire faster than we can backfill. Data and optimization gaps erode throughput, yield, and energy performance. Analyses summarized in LinkedIn commentary cite doubleŌĆædigit gains for targeted Industry 4.0 deployments and underscore downtime economics measured in six to seven figures per hour. That is enough to move modernization from discretionary to essential in many units. When you present the plan, relate each investment to risk reduction, uptime, safety, and measurable production lift, not just new software.

HoneywellŌĆÖs own modernization guidance emphasizes preserving existing graphics, control strategies, controllers, I/O processors, wiring, logic configurations, and native displays. In practice, this means standing up a modern Experion environment and migrating incrementally. A handsŌĆæon case study published by Electric Neutron describes a zeroŌĆædowntime pattern to Experion PKS R530 that I have seen echoed in the field: build a virtualized parallel stack, map databases and HMIs, bridge to legacy via Modbus and OPC, train operators with graphics imported and rationalized, and then stage cutover by loop criticality with rollback plans. The parallel environment reduces outage risk dramatically while you validate logic and displays offline and on a digital twin. On the data side, bringing Honeywell PHD or an equivalent historian online early helps you separate signal from noise, rationalize alarms, and give operators better trend context before the first loop cutover.

The nearŌĆæterm urgency for TDC 3000, given the December 31, 2025 support milestone communicated by Industrial Design Solutions, is to schedule phased transitions in calendar terms, align with planned outages, and reserve longŌĆælead parts and services. The preservation approach reduces training risk and protects your intellectual property while you harden cybersecurity and add modern analytics.

Yokogawa plants follow the same modernization physics. Although our notes did not include a vendor modernization brief for CENTUM, the standard playbook applies and is well documented by major automation suppliers. Start with HMI replication to protect operator situational awareness, then transition controllers and finally I/O. Use highŌĆæfidelity simulation to test new control modules, interlocks, and alarm behavior in the operatorŌĆÖs actual screens before cutover. Plan hot cutovers unit by unit to transfer loops without fullŌĆæplant outages, and maintain rollback procedures and sideŌĆæbyŌĆæside HMIs during commissioning. ThirdŌĆæparty migration programs from suppliers like ABB and Emerson demonstrate how adapters, cabinet reuse, and staged cutovers minimize reŌĆætermination and downtime. These methods are platformŌĆæagnostic and translate to CENTUM with careful engineering. Confidence for these CENTUMŌĆæspecific inferences is medium, and you should validate details with the vendor or an experienced system integrator.

Replication of operator displays is not just a comfort measure; it is a safety control. Replication preserves muscle memory and reduces changeover error. Innovation should then target highŌĆæperformance HMI principles, alarm rationalization, and better abnormal situation management. IEB Media highlights that HMI upgrades can happen with little or no downtime; you can test new displays against a simulation beside the legacy console and provide handsŌĆæon training before any live integration. Industrial Design Solutions emphasizes comprehensive operator training and continuous evaluation; that matches what works on site. In my projects, pairing scenarioŌĆæbased drills with a digital twin consistently lowers startup stress and shortens the stabilization period.

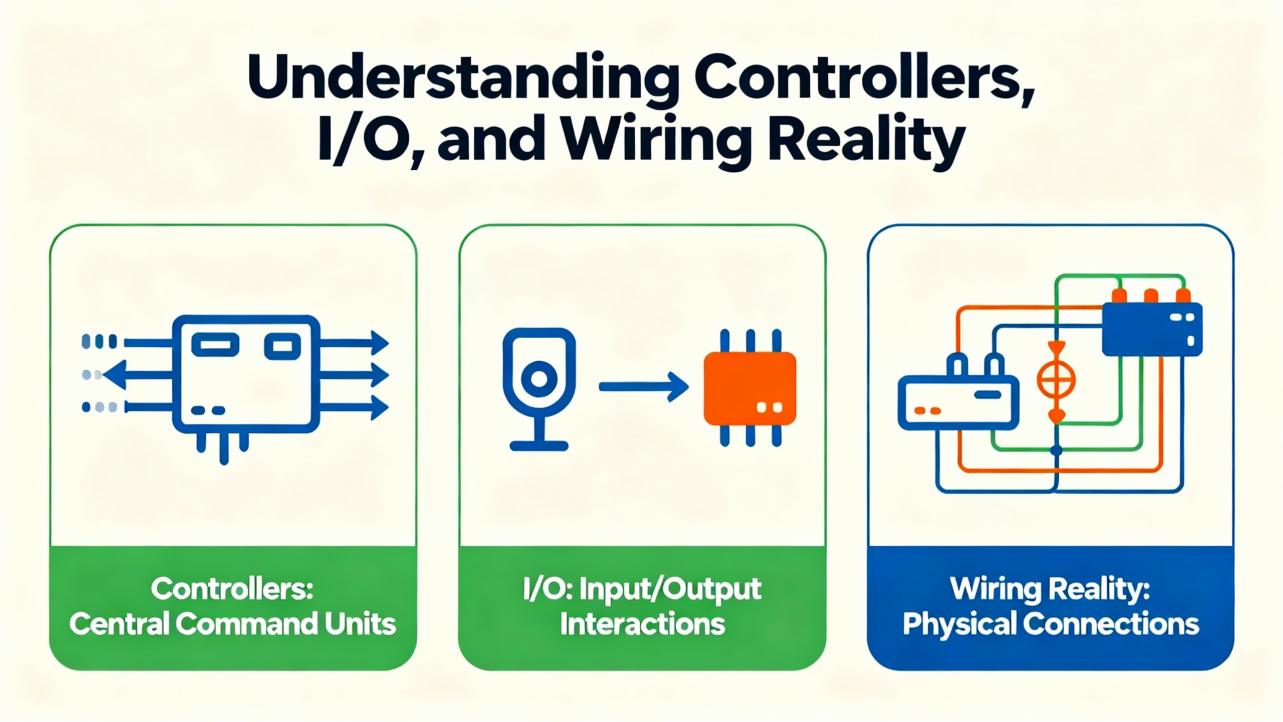

Controller replacement is where configuration errors become expensive, so make simulation fidelity your friend. Generate or import controller configuration, exercise it against realistic process models, and use I/O scanners or adapters to mimic or bridge legacy I/O during testing. I/O replacement is the last phase; save it for when HMI and controllers are steady. Suppliers document wiring kits and marshalling solutions that avoid mass reŌĆætermination. ABB publicizes broad migration toolsets for preserving existing I/O where feasible, and EmersonŌĆÖs white paper outlines flexible migration with parallel operation and adapters; both patterns reduce outage risk and installation scope. You do not need to start by touching every terminal strip in the plant.

Hot cutover minimizes downtime by converting loops one at a time in parallel operation. Cold cutover concentrates downtime into a single full shutdown. Most plants choose hot cutover unless a large planned outage and low startup risk make cold cutover attractive. IEB MediaŌĆÖs view aligns with my experience: hot cutover costs more in space and project complexity but often wins on total cost when you factor lost production and startup risk. Regardless of approach, establish clear criteria for go/noŌĆægo, rollback, and acceptance, and rehearse with the same crew that will execute the real thing.

Modernization is the right time to fix chronic data and security debt. Industrial Design Solutions recommends filtering and prioritizing data, deploying a historian such as Honeywell PHD to handle volume and retrieval efficiently, and automating processing for analytics. Cybersecurity should be builtŌĆæin rather than boltedŌĆæon: segment networks, harden endpoints, patch on a disciplined cadence, and enforce access control. Tie maintenance windows to production cycles so security and reliability work do not erode throughput. The upside is not only fewer incidents but better, faster decisions and a foundation for predictive maintenance.

IEB Media underlines the importance of project experience. For both TDC 3000 and CENTUM upgrades, choose partners who have executed multiple similar migrations and allow you to speak with reference plants. Ask to see their simulation environment and test plans, not just demos. Industrial Design Solutions calls out the importance of responsive vendor support; in crisis, that matters more than brochures. You can also evaluate thirdŌĆæparty migration offerings. ABB market materials describe TDC 3000 to 800xA conversions in the chemical sector, and Emerson publishes flexible migration and parallel operation patterns in its white papers. Use those as conceptual benchmarks even if you stay within the original vendorŌĆÖs ecosystem.

Here is a concise comparison grounded in notes and field practice. Where direct vendor specifics are not in the notes, I indicate that the cell reflects general DCS practice and field experience, with confidence noted.

| Topic | Honeywell TDC 3000 | Yokogawa CENTUM |

|---|---|---|

| Lifecycle status | Support and coax subsystem phaseŌĆæout communicated with a December 31, 2025 milestone via Industrial Design Solutions; modernization options actively promoted by the vendor. Confidence: high. | No specific lifecycle date found in notes; modernization expected to be lifecycleŌĆædriven and incremental. Confidence: medium (inferred). |

| Typical modernization target | Experion PKS with virtualization, graphics preservation, and staged migration, including zeroŌĆædowntime patterns reported by Electric Neutron. Confidence: high. | Migration to a modern CENTUM platform with HMI continuity and phased cutovers consistent with DCS best practice. Confidence: medium (inferred). |

| Preservation approach | Vendor emphasizes retention of graphics, logic, controllers, I/O processors, and wiring to protect IP and reduce risk (Honeywell Process Solutions). Confidence: high. | Operator HMI replication and staged replacement are standard DCS methods that apply to CENTUM projects. Confidence: medium (inferred). |

| Cutover pattern | Hot cutover favored to minimize downtime; parallel operation and loopŌĆæbyŌĆæloop transfer recommended (IEB Media). Confidence: high. | Same hotŌĆæcutover logic applies; success hinges on simulation and rollback discipline (IEB Media, Emerson). Confidence: high. |

| Data and historian | Honeywell PHD frequently used for efficient storage and retrieval and alarm/data management (Industrial Design Solutions). Confidence: high. | Comparable historian integration expected; solution choice depends on plant standards. Confidence: medium (inferred). |

| Cyber and patching | Multilayer defenses, patch governance, and monitoring called out by Industrial Design Solutions; modernization enables segmentation and secure remote access. Confidence: high. | Identical requirements apply; implement as part of the migration, not after. Confidence: high (general best practice). |

Start with an installedŌĆæbase assessment that inventories I/O counts, controller loads, graphics, sequences, interlocks, and interfaces. Build a risk map that links obsolescence, support exposure, and cyber posture to unit criticality and outage windows. Choose your strategic postureŌĆöreplication where stability is paramount and innovation where ROI is strongestŌĆöthen sequence HMI, controllers, and I/O accordingly. Stand up a virtualized parallel environment and wire it to a digital twin so you can run graphics and logic in anger before touching a live loop. Plan hot cutovers for units that cannot sit idle, and rehearse operator procedures, alarm responses, and rollback criteria. Align training with real screens and simulated events, and put your best shift leads at the console during the first cutovers. In parallel, establish historian, alarm rationalization, and cybersecurity baselines so your first day on the new system is better than your last day on the old.

Most upgrade pain comes from underestimating data and alarm volume, skipping simulation fidelity, and treating patching as an afterthought. Industrial Design Solutions highlights data overload and latency caused by poorly prioritized traffic; address this by segmenting networks, prioritizing control traffic, and placing controllers and sensors strategically. Hardware health and software quality suffer without preventive maintenance and disciplined change management; align maintenance with production cycles and enforce version control and test gates. Human factors are not soft issuesŌĆöoperator training and confidence determine startup quality. Put comprehensive training and sideŌĆæbyŌĆæside HMI trials on the critical path, not the niceŌĆætoŌĆæhave list.

Buy lifecycle, not logos. In practical terms, that means prioritizing backwardŌĆæcompatible architectures that preserve wiring and graphics, proven migration toolsets, and the partnerŌĆÖs record of hot cutovers in your process. Ask for a simulation demo with your graphics and a handful of your loops, not a sanitized vendor sample. Budget realistically for cybersecurity operations and compliance rather than pretending it is free. Plan for virtualization from day one to reduce hardware churn and make OS updates manageable. Finally, insist on measurable outcomes in the contractŌĆöfrom alarm flood reduction to timeŌĆætoŌĆæoperatorŌĆæcompetenceŌĆöso both sides are focused on performance, not just delivery.

If you run TDC 3000, the combination of coax and support milestones makes this a now problem, not a nextŌĆæyear problem. If you run CENTUM, you are on the same modernization curve even without a date circled in red. The winning pattern is consistent across vendors: replicate what protects operators, innovate where the ROI is clear, phase the work, simulate everything, and favor hot cutovers with disciplined rollback. Build cybersecurity and data foundations into the plan, not after it. Use experienced partners and require evidence, not promises. Do those things, and modernization becomes a controlled, valueŌĆægenerating change instead of a highŌĆærisk leap.

This article draws on modernization strategy coverage from IEB Media; Honeywell TDC/TPS modernization positioning from Honeywell Process Solutions; a TDC 3000 zeroŌĆædowntime migration case pattern as described by Electric Neutron; DCS operations and security practices summarized by Industrial Design Solutions; and industry economics and evolution commentary published on LinkedIn. Historical technical details for TDC 3000ŌĆÖs Advanced Process Manager and Universal Control Network derive from an archival document hosted on Scribd. Where I discuss Yokogawa CENTUM specifics without a direct vendor source in the notes, I extrapolate from crossŌĆævendor DCS best practice and field work; confidence for those inferences is medium.

Start by mapping operational risk and business goals. If your unitŌĆÖs risk profile and staffing make change difficult, replication keeps operator displays and logic behavior familiar while moving you onto supported hardware and OS baselines. If your constraints allow, innovationŌĆösmart I/O, redesigned highŌĆæperformance HMI, and advanced controlŌĆöusually delivers better lifecycle ROI by cutting alarm load, improving quality, and reducing unplanned downtime. IEB MediaŌĆÖs framing of these options is a useful planning lens.

Yes. A common and proven approach is to stand up a virtualized parallel Experion environment, import and rationalize graphics, bridge to legacy via Modbus or OPC, train operators sideŌĆæbyŌĆæside, and then hotŌĆæcutover loops in stages with rollback available. Electric Neutron details such a pattern for Experion PKS R530, and it aligns with what works on site. The key is highŌĆæfidelity simulation and disciplined test gates before touching a live loop.

They do. Even though our notes did not include a CENTUMŌĆæspecific vendor guide, the standard DCS modernization sequence of HMI replication, controller transitions, and finally I/O, all validated by simulation, applies. Hot cutovers with parallel operation and clear rollback criteria minimize risk. Confidence for this generalized guidance is medium; validate specifics with the vendor or an integrator who has executed CENTUM migrations.

Treat cybersecurity as an integral workstream. Segment networks to protect control traffic, harden and patch systems on a governed cadence, enforce roleŌĆæbased access, and set up monitoring and logging appropriate for OT. Industrial Design Solutions emphasizes that AV and patches must be current; modernization is your moment to get those baselines right. Do not bundle cyber into ŌĆ£postŌĆægoŌĆæliveŌĆØ punch lists.

Tie investments to avoided downtime, safety, and production improvements. Industry commentary aggregated on LinkedIn points to unplanned downtime costs in the sixŌĆæ to sevenŌĆæfigure per hour range in many sectors. Combine that with unitŌĆæspecific alarmŌĆæflood reductions, stabilization time targets, and energy/performance KPIs. It is easier to fund modernization when the financial logic is transparent.

If your inŌĆæhouse team lacks recent, relevant migration experience, it is often worth it. IEB Media highlights the role of experienced partners in planning, simulation, and execution. Ask for references, prior cutover artifacts, and a walkŌĆæthrough of their simulation environment. Your best partner is the one who can show their work, not just their marketing.

Leave Your Comment