-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In critical power and process plants, the governorŌĆōactuator pair is often the only thing standing between a controlled speed change and a runaway event. That is especially true for Woodward-based systems on engines, steam turbines, and emergency diesel generators.

Experience from the nuclear fleet underscores this point. The Nuclear Maintenance Applications Center at EPRI reviewed emergency diesel generator performance and found that governing system issues were the single largest contributor to emergency diesel unreliability and unavailability over several years. Much of that fleet uses Woodward governors such as UGŌĆæ8, EGA with EGBŌĆæC actuators, and 2301A with EGBŌĆæP actuators, together covering close to ninety percent of nuclear emergency diesel governor applications. When those systems misbehave, the plant immediately loses confidence in its last line of defense.

On the engine side, Ace Power Parts and Ace Power Products emphasize that a misadjusted mechanical Woodward governor can allow overspeed severe enough to shatter magneto magnets and damage hardware even with no load connected. The Woodward PGA Governor Manual likewise warns that poor governing can rapidly turn into a runaway condition that risks injury, loss of life, and major equipment damage. In practice, that means governor actuator faults are not ŌĆ£nice to fix when convenientŌĆØ; they are safety and availability problems.

The challenge is that erratic behavior at the fuel rack or steam valve does not automatically mean the actuator itself is faulty. Bartech Marine describes a case where a governor actuator looked unstable after engine overhauls. Bench testing later proved the actuator was perfectly healthy; a damaged control cable was injecting noise into the current loop and causing all the trouble. A detailed Woodward 505 steam turbine case shared on Control.com shows a similar pattern in reverse: the actuator and Voith hydraulic converter followed the mA signal perfectly, while the governor controllerŌĆÖs internal reference dropped unexpectedly and starved the actuator of demand.

Reliable diagnosis of Woodward governor actuator faults therefore demands a structured approach that treats the actuator as one component in a control loop, not as a black box to replace on suspicion.

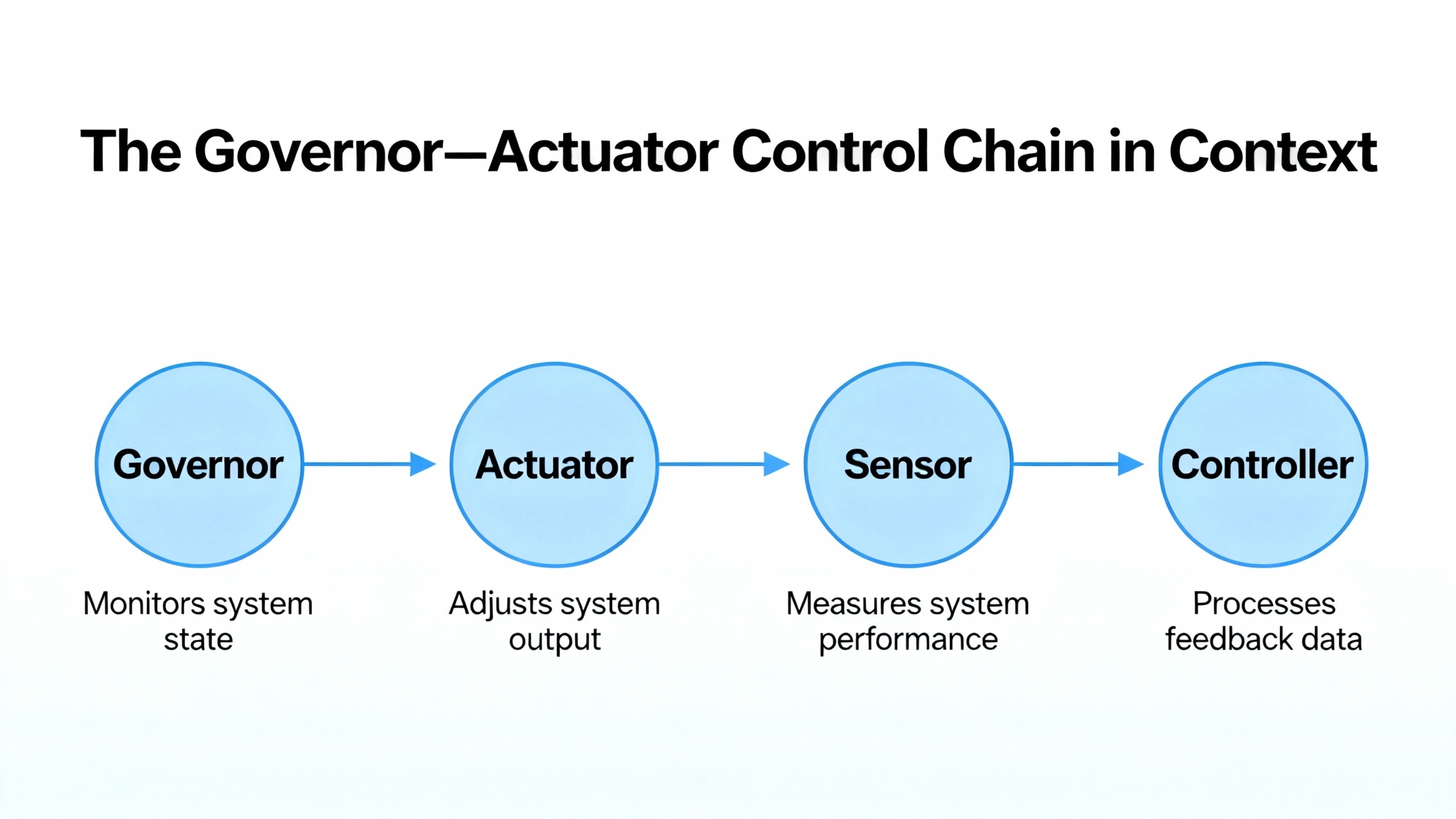

Before diving into procedures, it helps to frame where the actuator sits in the Woodward ecosystem.

On many industrial engines, Ace Power Products notes that a mechanical Woodward governor controls speed by regulating throttle position. The governorŌĆÖs internal mechanics sense speed and translate it, through springs and linkage, into motion at the throttle arm or fuel rack. In those systems, the ŌĆ£actuatorŌĆØ is often the hydraulic power head or linkage that converts the governorŌĆÖs motion into valve movement.

In nuclear emergency diesels, EPRIŌĆÖs guidance focuses heavily on Woodward UGŌĆæ8, EGA with EGBŌĆæC actuator, and 2301A with EGBŌĆæP actuator combinations. There, the governor may be mechanical, electronic, or a hybrid, but the actuator still does the same essential job: convert a governor output into a precise position of the fuel control mechanism.

Steam turbine applications add another layer. The Control.com case describes a Woodward 505 controller whose 0ŌĆō100 percent output is converted into a 4ŌĆō20 mA signal feeding an electroŌĆæhydraulic governor (EHG). The EHG then drives a Voith I/H converter to produce hydraulic pressure that moves nonŌĆælinear steam valve actuators. In this chain, an apparent actuator problem might actually originate in the 505 logic, the mA loop, the EHG, the I/H converter, or the mechanical valves.

Across these scenarios, the common thread is that the actuator sits between the governorŌĆÖs decision and the prime moverŌĆÖs fuel or steam valves. Fault diagnosis must therefore consider sensors, governor logic, output signal, actuator mechanics, hydraulic or oil systems, and the engine or turbine and its auxiliaries.

Several themes repeat across the Woodward PGA Manual, the EPRI emergency diesel guide, the Ace Power articles, the Bartech Marine case, and user experience captured on Control.com.

One principle is to treat safety as nonŌĆænegotiable. The PGA Governor Manual warns that when starting an engine or turbine, you must be prepared to execute an immediate emergency shutdown to prevent runaway or overspeed. In the field, that means confirming that shutdown devices, trips, and manual fuel shutoffs are functional before you begin any diagnostic runs.

A second principle is that poor governing can be caused by the governor and actuator or by the prime mover and its auxiliaries. The PGA manual explicitly notes that poor governing may stem from faulty governor performance, or from the governor attempting to correct for faulty operation of engine or turbine auxiliary equipment. Ace Power Products adds that surging and hunting are often caused by fuel or air issues, such as a partially plugged carburetor or a blocked idle circuit, rather than the governor itself. That means actuator diagnosis must include verification that the fuel, air, and mechanical drive systems are behaving.

A third principle is to prioritize basic mechanical and fluid health before diving into advanced tuning. The Woodward PGA Governor Manual points out that dirty oil is responsible for about half of all governor troubles. Contaminated oil, especially when mixed with water, foams and corrodes internal parts. Similarly, Ace Power Parts stresses checking springs, linkages, and free play before touching adjustment screws. Fixing oil and linkage issues often resolves symptoms that initially looked like deeper actuator faults.

A fourth principle is to verify signals and wiring, not just hardware. Bartech MarineŌĆÖs workshop test of a ŌĆ£suspiciousŌĆØ actuator confirmed it responded perfectly to a clean mA control signal on a test rig. The real fault was a damaged cable on site. The Control.com Woodward 505 case also hinges on signal verification: the Voith I/H converter faithfully followed the mA command from the 505; the 505 reference logic itself was pulling the demand down. In practice, that means measuring the mA loop with an ammeter, using a simulator to stroke the actuator, and inspecting cables and connectors before condemning the actuator.

A final principle is to use divideŌĆæandŌĆæconquer logic when troubleshooting. Experienced contributors on Control.com recommend systematically ruling out each part of the chain: governor controller, output driver or EHG, I/H converter, actuator body, and valve mechanics. EPRIŌĆÖs guidance follows a similar pattern, combining failure data with structured troubleshooting and postŌĆæmaintenance testing. The more disciplined your separation of functions, the less you will waste on unnecessary actuator overhauls.

With those principles in mind, the following sections outline practical diagnostic procedures for both mechanical and electrohydraulic Woodward actuator arrangements.

Mechanical Woodward governors with hydraulic power heads and linkageŌĆætype actuators remain common on smaller engines and legacy generator sets. The Ace Power Parts and Ace Power Products articles, combined with the Woodward PGA Governor Manual, provide a practical roadmap for field diagnosis.

Start by characterizing the complaint in plain language. Common patterns noted by Ace Power Parts include engines that run too fast, run too slow, or exhibit speed instability such as surging or hunting. The PGA manual defines ŌĆ£huntŌĆØ as a rhythmic variation in speed that disappears when the governor is manually blocked but returns when the governor is reŌĆæengaged.

If there is any suggestion of overspeed, treat the situation as a safety issue. Confirm that the mechanical and electrical shutdown arrangements are functional and that you can quickly cut fuel or steam. Remember the realŌĆæworld outcome described by Ace Power Parts: a misadjusted governor allowed enough overspeed to shatter a magneto magnet into pieces. This is the type of event you are trying to prevent by planning shutdown paths before you touch the system.

Before changing any settings, follow Ace Power ProductsŌĆÖ approach and inspect the mechanical linkage and spring system carefully. Confirm that all external governor parts move freely through their full travel without binding. Make sure the governor spring is not stretched, damaged, or hooked into an improvised location.

Check for free play between the carburetor or fuel rack and the governor spindle. Excessive play means that the governorŌĆÖs motion will not be transmitted properly to the throttle, causing deadband, lag, and hunting. The goal of static linkage adjustment is to eliminate this slack so that the governor has direct, predictable control over the fuel device.

The Woodward PGA Governor Manual instructs that the oil level be maintained between the marks on the level gauge glass while the unit is operating. The correct level is at the joint line between the power case and column, corresponding to the upper mark on the glass, and should not be higher. Any warning decals near the gauge should be followed exactly.

The same manual states plainly that dirty oil causes approximately fifty percent of all governor troubles. That statistic alone justifies making oil inspection one of the first diagnostic steps. Use only clean new oil or properly filtered oil, and ensure that containers used to fill the governor are perfectly clean. If you see milky oil or signs of water, assume the oil has broken down; waterŌĆæcontaminated oil foams and attacks internal surfaces, degrading both damping and response.

In practice, many ŌĆ£mysteriousŌĆØ actuator instabilities on mechanical Woodward units are resolved by an oil change followed by thorough flushing of contaminated cavities.

With clean oil and good linkage, move to static adjustment. Ace Power Parts describes a practical static adjustment check used on many mechanical installations. With the engine stopped, place the throttle in the full open position and observe the governor shaft. If the shaft tends to rotate clockwise under spring force, loosen the clamp screw that couples the governor to the throttle shaft. Then rotate the shaft clockwise while keeping the throttle at full open, and retighten the clamp. The goal is to align the governorŌĆÖs neutral position with the throttleŌĆÖs full range, eliminating any deadband.

After this adjustment, manually move the throttle from idle to full open and verify that the governor and actuator linkage travel smoothly and fully, without hitting stops prematurely. Always consult the specific engine and governor manual for your model, because the exact direction of rotation and alignment marks may vary.

Once static adjustments and oil are correct, test the governor and actuator with the engine running at idle. Ace Power Products recommends manually moving the governor lever to open the throttle while watching the systemŌĆÖs reaction. A healthy governor and actuator will push the arm back toward idle as speed rises, resisting overspeed. If, during this test, the engine races and the governor does not push back, either the static adjustment is incorrect or internal governor parts may be worn or damaged.

If you want to isolate the governorŌĆÖs internal mechanism more precisely, Ace Power Products suggests temporarily removing the governor spring during a controlled test, so the governor is not being biased toward a speed setpoint. If even in that condition the internal flyweights and linkages do not develop a restoring force as speed rises, a professional repair shop or overhaul is likely required.

Speed instability complaints are often traced to nonŌĆægovernor causes. Ace Power Products emphasizes that surging or hunting is frequently due to fuel and air problems such as partially plugged carburetors, worn throttle shafts, or restricted idle circuits. The Woodward PGA Manual reinforces that auxiliary equipment can have major impact on overall governing.

In the field, a simple but effective test is to temporarily block the governorŌĆÖs action and observe the engine. If the engine still hunts when the governor is effectively taken out of control, the prime mover, carburetor, fuel system, or load is the likely culprit. Only when the engine runs smoothly without governor action, yet becomes unstable when the governor and actuator are reŌĆæengaged, should you zero in on governor dynamics and actuator response.

If, after confirming fuel and air are correct, the governor still appears overly sensitive, Ace Power Products recommends reducing sensitivity by moving the governor spring attachment to a different hole further from the axis, reducing leverage. Alternatively, selecting an appropriate spring based on the engine manual or consultation with a repair shop can tame an overly nervous actuator without compromising stability.

Modern Woodward systems frequently use electronic controllers and electrohydraulic actuators. Diagnosis in these systems demands careful separation of controller logic, signal path, actuator mechanics, and hydraulics. The Bartech Marine case and the Woodward 505 steam turbine discussion on Control.com illustrate practical techniques.

In Bartech MarineŌĆÖs incident, an engine equipped with a governor actuator initially ran well at half load and full load after cylinder liner replacement. Later, the engine shut down even though all monitored parameters remained within limits. On subsequent attempts to start and load, the governor actuator displayed erratic behavior, leading the onŌĆæsite team to suspect the actuator.

Bartech removed the actuator and sent it to their governor bay. On a dedicated test rig, with a controlled mA signal applied, the actuator behaved perfectly. It responded smoothly and stably across the entire current range, proving that the actuator hardware was not at fault. This simple bench test prevented an unnecessary actuator overhaul and shifted attention back to the control loop.

Whenever practical, follow this pattern. If you suspect an electronic or electrohydraulic Woodward actuator, remove it and exercise it on a knownŌĆægood test stand or with a certified current source. If the actuator strokes cleanly with correct hysteresis and no unexplained jumps, you should regard it as healthy until proven otherwise.

In the same Bartech case, an electrical inspection back at the plant uncovered the real culprit: a damaged cable in the control system, which was corrupting the actuator command signal. Once the cable was replaced, the erratic behavior disappeared.

This highlights an essential diagnostic rule. Never assume that the signal coming to the actuator is clean just because a controller display looks normal. Use an ammeter in series with the actuator coil, or a dedicated loop calibrator, to measure the actual mA reaching the actuator terminals. Inspect plugs, junction boxes, and any intermediate analog input or output modules for loose terminations, corrosion, or water ingress.

If the actuator shows erratic motion and your current reading shows noise, dropouts, or implausible values, address the signal path first. Only if the current remains clean while the actuator behaves poorly should you consider actuator internal faults.

The Control.com discussion of a steam turbine with a Woodward 505 controller and Voith hydraulic equipment offers a clear illustration of controller versus actuator diagnosis.

In that plant, a 0ŌĆō100 percent demand from the 505 was converted into a 4ŌĆō20 mA signal for an electrohydraulic governor, which in turn drove a Voith I/H converter to supply oil pressure to nonŌĆælinear steam valve actuators. During synchronization and loading attempts, when operators tried to raise load to around nine megawatts, the actuator initially opened as expected. Shortly afterward, the 505 reduced its output, causing the valve to close and the unit to approach reverse power.

Trend data showed that the Voith converter was faithfully following the decrease in mA command from the 505. There was no feedback signal from the valve back to the 505; the controllerŌĆÖs output was based solely on its internal logic combining load, speed, droop, and valve limiting functions. The internal ŌĆ£referenceŌĆØ value inside the 505 dropped from roughly thirtyŌĆætwo percent to about twentyŌĆætwo percent as load was raised.

From a diagnostic perspective, this pattern indicates that the actuator and hydraulic equipment were doing exactly what they were told. The fault was in the controller logic, configuration, or protective functions pulling the reference down, not in the actuator.

For this kind of system, a practical diagnostic technique recommended on Control.com is to stroke the actuator using a standalone mA simulator with the turbine offline. With steam isolated but the hydraulic system running, apply 4ŌĆō20 mA to the actuator input and confirm that the valve or servo moves smoothly through its operating range. In parallel, install an ammeter on the real controller output circuit and log the controllerŌĆÖs actual current during both simulated tests and real synchronization attempts. If commanded current does not increase when expected, the problem lies upstream in the governor controller. Only when commanded current rises but movement does not follow should suspicion shift to the Voith converter or actuator mechanics.

Because the Woodward 505 has limited onboard diagnostics and few userŌĆæserviceable parts, the Control.com discussion notes that many plants keep a spare controller. BenchŌĆæconfiguring the spare with identical parameters and swapping it into service during a planned outage is often the most efficient way to separate a hardware failure from a configuration or logic issue.

Taken together, the Bartech Marine case and the Woodward 505 example illustrate the value of structured, divideŌĆæandŌĆæconquer diagnosis in electrohydraulic Woodward chains. First confirm actuator hardware using a test rig or mA source. Next verify the integrity of the signal path and cabling. Then observe whether the controller is actually commanding the motion you expect. Only after those elements are proven should you dig into controller internals or specialized hydraulic hardware.

This mindset mirrors the broader EPRI approach for nuclear emergency diesel governors, where failure databases are combined with testing guidance and troubleshooting examples. The underlying message is that governor actuator diagnosis is most effective when you deliberately separate mechanical, hydraulic, electrical, and logical domains and test each in isolation where possible.

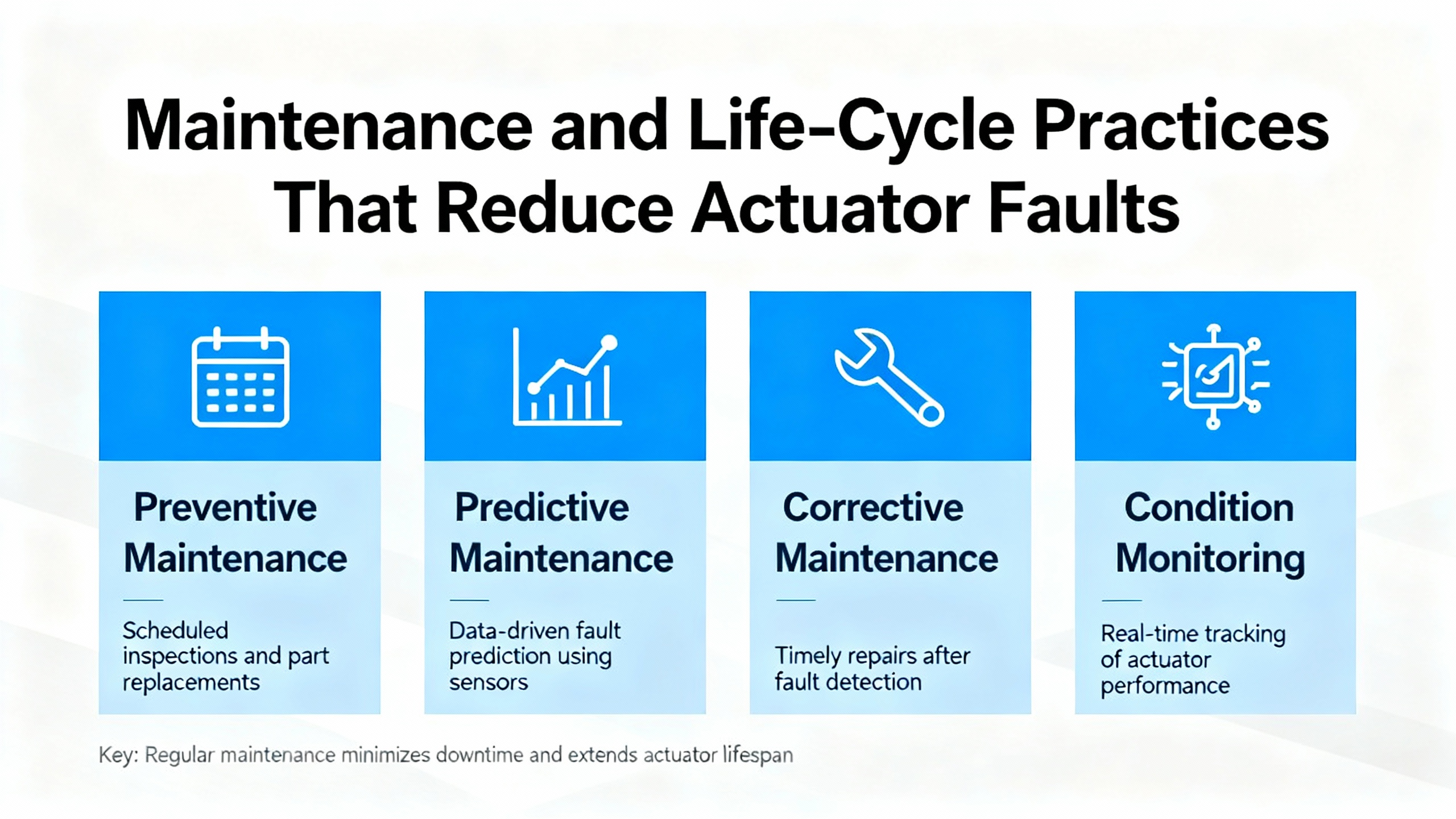

Many apparent actuator problems are symptoms of broader maintenance and lifeŌĆæcycle gaps. The sources combined provide several concrete lessons.

The Woodward PGA Governor Manual is clear that oil maintenance is critical. Maintaining the oil level at the joint line and using only clean, uncontaminated oil addresses roughly half of governor troubles. In practice, that means integrating governor oil checks into routine rounds, treating any signs of water contamination as a maintenance priority, and ensuring that makeup oil is handled in clean containers.

Ace Power ProductsŌĆÖ focus on springs and linkage tells the same story in mechanical terms. Governor springs stretch over time, linkage holes wear, and improvised adjustments accumulate. Restoring factory geometry and free movement often stabilizes an actuator that had been unfairly blamed for poor governing.

EPRIŌĆÖs emergency diesel governor guide adds a lifeŌĆæcycle dimension. Older Woodward EGA systems from the nineteenŌĆæfifties and nineteenŌĆæsixties are now clearly obsolete, with aging hardware and parts shortages threatening reliability. Refurbishment issues with 2301A electronic governors and associated actuators, combined with regulatory deviation reports under 10 CFR Part 21, have forced utilities to confront obsolescence. Utilities are encouraged to treat these governors and actuators as critical assets that require structured maintenance programs, documented tuning procedures, and postŌĆæmaintenance testing.

In practice, what often gets labeled on a work order as an ŌĆ£actuator faultŌĆØ is a combination of dirty oil, worn springs, obsolete electronics, or incomplete postŌĆæmaintenance testing. Aligning your practices with the themes from EPRI, Woodward manuals, and experienced field shops like Ace Power Products and Bartech Marine can significantly reduce unplanned actuator interventions.

The following table synthesizes the research notes into a quick reference that links observed symptoms to probable areas and suggested diagnostic emphasis. It is not a substitute for manufacturer manuals but can help structure your thinking in the field.

| Observed symptom | Likely focus area | Key diagnostic emphasis |

|---|---|---|

| Engine runs too fast or overspeeds on light load | Mechanical governor and actuator linkage | Verify linkage and static adjustment; check spring condition; be ready to trip safely. |

| Engine speed hunts or surges at steady load | Fuel and air system, then governor dynamics | Rule out plugged carburetor and idle circuit; then review governor sensitivity. |

| Slow return to rated speed after a load or speedŌĆæsetting change | Governor compensation settings and oil condition | Check compensating needle valve adjustment and governor oil cleanliness and level. |

| Actuator motion appears erratic despite normal controller display | Command signal wiring and mA loop integrity | BenchŌĆætest actuator with clean mA signal; inspect and test cabling and terminations. |

| Valve or rack does not open sufficiently during load increase, causing reverse power risk | Governor controller logic and configuration (for example, Woodward 505) | Measure actual output current; observe internal reference behavior and limits. |

| Frequent governing issues in critical standby diesels | Obsolescence and maintenance of UGŌĆæ8, EGA, 2301A and associated actuators | Review EPRI guidance, parts condition, and postŌĆæmaintenance testing practices. |

Every row in this table maps back to details in the Woodward PGA Governor Manual, Ace Power ProductsŌĆÖ mechanical governor articles, the Bartech Marine case, the Control.com Woodward 505 discussion, and EPRIŌĆÖs nuclear emergency diesel governor maintenance guide. Using this matrix as a mental checklist ensures that actuator diagnosis remains anchored in systemŌĆælevel thinking.

The Woodward PGA Governor Manual defines hunting as a rhythmic speed variation that disappears when you block governor operation manually but returns when the governor is put back in control. In practice, that definition is also a diagnostic method. If you temporarily isolate or block the governor and the engine still hunts, the root cause is likely in the fuel system, carburetion, air supply, or load. Ace Power Products reports that partially plugged carburetors and idle circuits are common culprits. If the engine runs smoothly without the governor but begins hunting only when the governor and actuator are reŌĆæengaged, you should investigate governor sensitivity, compensation settings, spring location, and oil condition.

Ace Power Products recommends referring units to a professional repair shop when static adjustment checks fail repeatedly, when the governor does not push the lever back toward idle during manual testing, or when there is obvious internal wear or contamination. Bartech MarineŌĆÖs case shows another trigger point: if the actuator tests unstable on site but behaves perfectly on a test rig with a clean mA signal, the problem lies elsewhere, and the shop can provide a definitive health assessment. In highŌĆærisk environments such as nuclear emergency diesels, EPRI suggests using structured troubleshooting and bench testing to decide when an overhaul or replacement is warranted rather than relying on subjective impressions.

Based on the Woodward PGA Governor Manual, keeping the governor oil clean and at the correct level is arguably the single highestŌĆæleverage preventive action. The manual attributes about half of all governor troubles to dirty oil. Ensuring that only clean oil in clean containers ever reaches the governor, that water contamination is corrected promptly, and that level is held at the power case joint line will dramatically reduce the number of actuator behaviors that appear mysterious but are actually just fluidŌĆærelated.

In the field, a Woodward governor actuator rarely fails in isolation. When you treat it as one link in a chain and follow disciplined procedures grounded in Woodward manuals, EPRI guidance, and realŌĆæworld cases from firms like Ace Power Products and Bartech Marine, you stop guessing, stop swapping parts blindly, and start restoring stable, safe speed control with confidence. That is the standard every serious industrial automation engineer should aim for on every governor job.

Leave Your Comment