-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Walk into almost any process plant or manufacturing line today and you are looking at a multigenerational, multi-vendor environment whether you planned it or not. ISA has highlighted that roughly half of North American plants are running automation systems with components that are at least twenty years old, and thirty-year-old hardware is not unusual. Over those decades, vendors have merged, disappeared, or pivoted to new platforms. Spares get obsoleted. HMIs, PLCs, drives, and field devices are replaced piecemeal. The result is a patchwork of brands and vintages that all need to cooperate if production is going to run.

At the same time, business pressure is rising. Calvary Robotics points out that standardization and interoperability are now central to scaling, reducing complexity, and controlling cost. Pneumatic and motion manufacturers are offering cross-brand interface kits that promise 85ŌĆō95% compatibility across major brands while cutting spare-part inventory and maintenance costs. Component suppliers are publishing cross-reference guides to help engineers find plug-compatible substitutes when original parts are no longer available.

The question is no longer whether you will run cross-brand components. You already are. The real question is whether you will treat cross-brand compatibility as a deliberate engineering discipline or allow it to evolve as a series of crisis-driven hacks.

As someone who spends a lot of time in front of live panels and machines during planned shutdowns and weekend emergencies, I have seen both approaches. Plants that plan compatibility achieve clean migrations, leaner inventory, and predictable behavior. Plants that improvise live with ghost faults, undocumented adapters, and chronic delays every time something fails. This article is about how to land in the first group.

Electronic and mechanical industries use the FormŌĆōFitŌĆōFunction model to describe compatibility. Cross-referencing specialists describe it this way:

Form is the physical shape, dimensions, and package outline. Fit is how the component mates with the rest of the system, including footprints, mounting, and connectors. Function is the electrical or operational behavior.

A cross-referencing guide for electronic components explains that dropŌĆæin replacements match form, fit, and function, pinŌĆætoŌĆæpin compatible parts share package and pin layout but still need behavioral verification, and functionally equivalent parts match the key performance but may require mechanical changes and reŌĆæqualification. Those distinctions map almost perfectly onto industrial automation.

In automation work, you need to extend FormŌĆōFitŌĆōFunction across several layers. Mechanical form and fit are obvious when you try to mount an SMC cylinder where a Festo unit used to sit and discover that the rail profile or bolt pattern does not line up. Pneumatic articles on rodless cylinders describe exactly this issue and show that standardized adapters for ports, mounting patterns, and rail dimensions are what turn nominally incompatible products into dropŌĆæin options.

The electrical layer covers power supplies, I/O types, and sensor interfaces. A part can bolt up mechanically and still be unusable because it expects a different voltage range or sinks current where the PLC is wired for sourcing inputs.

The control and communication layer covers fieldbuses and protocols such as Modbus, OPC UA, MQTT, BACnet, or vendorŌĆæspecific motion networks. Building integration specialists emphasize that interoperability (the basic ability to talk using a common protocol) is not the same as integration, which is about making multiple interoperable systems work as a single, coordinated whole.

Finally, there is functional compatibility in the sense that actually matters in operations: does the combined, crossŌĆæbrand system deliver the performance, safety, and behavior the process requires, under real loads, with real operators? A compressed air provider notes that two compressors with similar nominal flow can behave very differently in thermal performance, control strategy, and maintenance needs once they are on the plant floor. The same is true for PLCs, drives, and actuators.

The table below is how I think about compatibility when I am asked, ŌĆ£Can we drop Brand B into Brand AŌĆÖs footprint without trouble?ŌĆØ

| Compatibility dimension | What you must verify in practice | Typical failure if you skip it |

|---|---|---|

| Mechanical form | Envelope, port locations, rail or rod spacing, door clearances, HMI cutout | Interference, inability to mount, or misalignment causing premature wear |

| Mechanical fit | Bolt patterns, thread standards, orientation options, keying and latching | AdŌĆæhoc drilling, stacked adapters, stress concentrations, or mislocated loads |

| Electrical and power | Voltage levels, current, inrush, I/O types, sensor power, grounding approach | Nuisance trips, blown fuses, noisy signals, or damaged modules |

| Control and protocols | Fieldbus type, addressing, data models, timing, supported profiles | Gateways everywhere, partial data visibility, or devices that fall offline under load |

| Functional behavior | Response times, cycle time, accuracy, duty cycles, environmental limits | Meeting specs in the catalog but missing cycleŌĆætime, quality, or uptime targets in reality |

| Safety and compliance | Safety integrity level, certifications, approvals, standards alignment | Inability to validate safety systems, audit failures, or blocked installations |

| Life cycle and support | Vendor roadmaps, endŌĆæofŌĆæsupport dates, availability of tools and spares | BrandŌĆænew but already near endŌĆæofŌĆælife hardware, or stranded configurations |

Cross-brand compatibility means checking each of these dimensions deliberately instead of assuming that a part number match or a simple footprint drawing is enough.

One path is to stay mostly inside a single vendorŌĆÖs ecosystem and use their multigenerational upgrade strategy. ISA describes this as an ŌĆ£upgradeŌĆØ rather than a ŌĆ£migration.ŌĆØ You retain the vendor and architecture but introduce newer controllers, HMIs, and I/O in phases. Many large control vendors support this model with compatible backplanes, dropŌĆæin CPU upgrades, and bridging modules that allow older and newer nodes to coexist.

The upside is obvious. You get coherent tools, consistent HMIs, a single support channel, and a longŌĆæterm roadmap. ISAŌĆÖs experience is that when plants plan these multigenerational upgrades thoughtfully and track support end dates for each node, they can manage twentyŌĆæyear horizons with predictable cost and risk.

The downsides are just as real. You stay locked into one vendorŌĆÖs pricing and product strategy. If that vendor retires a platform earlier than expected or gets acquired, your clean roadmap becomes uncertain. And you are still exposed if physical components, such as pneumatic actuators or specialty sensors, are sourced from other brands.

Even if you choose this path for control, you need a crossŌĆæbrand strategy for everything around it, from mechanical actuators to smart field devices.

When a component goes obsolete, cross-reference systems are often the first tool on the bench. Cross-reference platforms described by Kruse and P3 America act as centralized databases that relate part numbers and specifications across multiple manufacturers. In precision components such as potentiometers, a cross-reference guide can map a discontinued part from one brand to an equivalent offered by another.

Specialist guidance for electronic components stresses that good crossŌĆæreferencing is not just partŌĆænumber mapping. It requires checking key parameters across electrical, mechanical, environmental, and firmware dimensions and applying the FormŌĆōFitŌĆōFunction model rigorously. The same article distinguishes three practical types of substitutes: dropŌĆæin replacements that match all three dimensions, pinŌĆætoŌĆæpin compatible parts that require functional verification, and functionally equivalent parts that need mechanical redesign.

Applied to automation components, that means treating each crossŌĆæbrand substitution as a miniŌĆæengineering project rather than a purchasing shortcut. For example, a crossŌĆæreferenced sensor may share thread type and electrical range but lack the necessary temperature rating or certification for a washdown or hazardous area. A servo drive with the same power rating may miss a required safety function.

The advantage of disciplined crossŌĆæreferencing is speed and resilience. You can source spares from multiple vendors, avoid line stoppages when a specific brand is out of stock, and design for multiŌĆæsourcing from day one. The risk is that if you treat the crossŌĆæreference table as the final answer instead of the starting point for verification, you can introduce hardŌĆætoŌĆædiagnose failures into production.

Cross-brand compatibility is very visible in pneumatic systems. A detailed rodless cylinder study shows what happens when you treat interface adaptation as a firstŌĆæclass engineering discipline instead of a series of adŌĆæhoc brackets and fittings.

The author describes working with a pharmaceutical manufacturer that maintained separate spare inventories for three brands of rodless cylinders. By standardizing interface adapters, mounting plates, and sensor conversions, they achieved 85ŌĆō95% crossŌĆæcompatibility between major brands, consolidated inventory by 42%, cut emergency orders by 78%, and reduced annual maintenance cost from $342,000.00 to $263,000.00. Average replacement time dropped from 4.8 hours to 1.3 hours, and the proportion of crossŌĆætrained technicians rose from 40% to 90%.

The technical approach breaks down into a few repeatable patterns.

Pneumatic port conversion handles different thread standards and orientations. Typical port conversions include Festo G1/8 to SMC M5, SMC Rc1/4 to Festo G1/4, and Festo G3/8 to SMC Rc3/8 using direct thread adapters, conversion inserts, or replacement port blocks. Orientation is adjusted with angled adapters and manifolds so that hoses and cables do not have to be rerun.

Mounting standardization uses universal plates, slotted brackets, and adjustable systems to translate different bolt patterns such as Festo 25 mm to SMC 20 mm or brandŌĆæspecific foot mounts, while respecting load ratings and alignment. HighŌĆæstrength materials and reinforced mounting points keep deflection and vibration within limits.

Sensor and feedback integration adapts TŌĆæslot, CŌĆæslot, and brandŌĆæspecific switch mounts with universal brackets or profile conversion rails. Electrical signal conditioning modules handle different voltage levels, current requirements, and signal polarity while calibration strategies account for different sensing distances and hysteresis.

Rail adaptation tackles different rail widths, heights, and hole patterns for guided rodless systems. Precision spacers, machined adapter plates, and structural reinforcement make it possible to crossŌĆæmount different brand rails while typically preserving 90ŌĆō95% of the original load capacity.

That pharmaceutical project followed a structured methodology. It began with a compatibility assessment by documenting fortyŌĆæseven existing configurations and fourteen critical interface variations, then moved into adapter selection and custom design where needed, and finally executed controlled implementation with leak tests, alignment verification, and performance validation under real operating conditions. Documentation and internal standards closed the loop so future replacements followed the same pattern instead of reverting to oneŌĆæoff fixes.

The same method applies whenever you want to normalize pneumatics, linear guides, or mounts across brands: treat mechanical and sensor interfaces as a product in their own right, not an afterthought.

Compatibility at the data and control layer depends on standards. A LinkedIn engineering note on automation compatibility points out that a primary source of incompatibility is divergent standards and protocols. The recommendation is simple: deliberately choose communication protocols that are widely supported and actively maintained in your domain. For industrial automation, families such as OPC UA, MQTT, and Modbus are frequently cited as good foundations, alongside quality and safety standards like ISO 9001, IEC 61508, and ISAŌĆæ88.

In building automation, experts emphasize open protocols such as BACnet and Modbus, combined with hardwired signals for basic safety interlocks. They distinguish between interoperability, which rests on common protocols, and full integration, which uses those protocols to coordinate HVAC, lighting, metering, and other systems into one coherent whole. One industry association reports that integrated systems can even deliver significant cable savings when they share pathways and infrastructure, further strengthening the business case for standardsŌĆæbased integration.

In industrial automation more broadly, an article on open automation points out that many vendors still bundle tightly coupled hardware and proprietary software. Even within a single brand, engineers often encounter different tools for PLCs, servos, and drives, which complicates crossŌĆæbrand collaboration and even internal standardization. The emerging alternative is open, softwareŌĆæcentric platforms based on standards such as IEC 61131ŌĆæ3 for PLC programming and IEC 61499 for eventŌĆædriven, functionŌĆæblockŌĆæbased systemŌĆælevel modeling.

Vendors have started to ship systems that embody these ideas. DeltaŌĆÖs engineering environment consolidates selection, configuration, and network debugging across PLCs, HMIs, servos, and drives to reduce closed workflows. Bosch RexrothŌĆÖs ctrlX platform uses a Linux base, web engineering, and open interfaces to blur the lines between OT and IT and is reported to reduce engineering workload by around thirty to fifty percent. Schneider ElectricŌĆÖs EcoStruxure Automation Expert uses IEC 61499 to decouple software from hardware and support ŌĆ£plug and playŌĆØ production applications that can run across different vendorsŌĆÖ devices.

HardwareŌĆæsoftware integration specialists emphasize that standard protocols are only part of the story. RealŌĆætime demands in automation put pressure on both hardware and software, and multiŌĆævendor compatibility must be validated with careful design, robust middleware, and extensive testing such as hardwareŌĆæinŌĆætheŌĆæloop simulations. Otherwise, protocolŌĆæcompatible components may still fail to meet latency and determinism requirements.

Open architectures and standards are the longŌĆæterm path to crossŌĆæbrand compatibility that does not collapse under its own complexity, but they demand intentional design and deep collaboration between vendors, integrators, and end users.

Between a clean, open architecture and a singleŌĆævendor ecosystem lies the world of boltŌĆæon gateways and crossŌĆæplatform addŌĆæons. ISA warns that these boltŌĆæon solutions are often oversold and should be treated as temporary bandŌĆæaids or interim steps in a phased migration, not as permanent architectures. In the field, that matches what many of us see: protocol converters stacked in panels, bespoke scripts moving data between MES and older PLCs, and multivendor HMIs scraping tags through fragile interfaces.

These tools have their place. They can allow an older line to talk to new analytics platforms or let a new device coexist with legacy controllers during a transition. But if you base your strategy on them, you inherit their fragility and support challenges.

A better pattern is to use boltŌĆæons deliberately as scaffolding. Design the endŌĆæstate architecture around open protocols and clean interfaces, deploy gateways to bridge the gap temporarily, and then retire them as you bring subsystems onto the target platform.

CrossŌĆæbrand design becomes dangerous when it ignores environmental limits, safety integrity, or regulatory requirements. The crossŌĆæreferencing community emphasizes that electrical compatibility alone is not sufficient. Environmental ratings such as operating and storage temperature, humidity, vibration, and thermal resistance, along with domainŌĆæspecific grades like automotive or military qualifications, are critical in harsh applications. A component that is technically equivalent at room temperature may fail early in a hot enclosure or on a vibrating machine.

Similarly, compliance attributes such as RoHS and REACH status, UL or CSA listings, CE or FCC markings, and sectorŌĆæspecific approvals can be hard constraints. A substitute sensor lacking the appropriate approval might look perfect on paper but be unusable in a regulated facility. If you are replacing contactors, safety relays, or motion components in a safety instrumented system, you must also verify that the safety ratings and diagnostic coverage match the original design and that the system still complies with standards such as IEC 61508.

All of this becomes harder in a multiŌĆævendor environment, which is exactly why crossŌĆæbrand compatibility cannot be reduced to matching a few catalog numbers.

Compatibility issues often surface first as performance problems. ISA warns that new HMIs and controllers can significantly increase traffic and processing load on existing networks, especially when old and new HMIs are run in parallel during cutover. Plants that skip capacity studies and network evaluation sometimes discover this the hard way when segments crash or response times degrade during commissioning.

The compressor industry provides a useful analogy. A compressed air specialist notes that similar nameplate flow ratings do not guarantee equivalent realŌĆæworld performance, because efficiency, control schemes, and thermal behavior differ between brands. The same concept applies when you swap drives, actuators, or controllers. On paper everything looks compatible; under actual process conditions, you see longer cycle times, unexpected delays, or inconsistent behavior.

HardwareŌĆæsoftware integration experts stress that multiŌĆævendor systems must be designed to meet realŌĆætime constraints, not just nominal specs. That usually means modeling or testing under realistic loads and using tools like hardwareŌĆæinŌĆætheŌĆæloop simulation before you trust a crossŌĆæbrand combination on a critical process.

When you switch brands, compatibility does not stop at the panel. A compressed air guide points out that brand changes reset your maintenance history. Service logs, wear patterns, and failure modes for the old unit do not transfer. You need a fresh baseline for runtime, pressure drops, and output trends and a new preventive maintenance plan tailored to the new equipment.

Operator and technician training also changes. Warning lights, fault codes, HMIs, and control logic differ by brand. Even brief, handsŌĆæon orientations on new interfaces and alarm logic can significantly reduce misuse and downtime. Automation components are no different. An HMI from one supplier may present alarms very differently than another. Drives and motion controllers from different vendors may use different parameter naming and diagnostic codes.

Inventory is another hidden cost. The compressor article notes that spare parts such as belts, filters, and sensors often become obsolete after a brand switch. Without a crossŌĆæbrand strategy, factories accumulate shelves of parts that no longer fit current equipment. The rodless cylinder case study demonstrates that a compatibility program can reverse this trend: standardized interfaces and adaptation allowed one manufacturer to reduce unique spareŌĆæpart items from 187 to 108, with corresponding reductions in emergency orders and maintenance cost.

The procurement and vendor chain changes as well. The compressor discussion highlights the importance of evaluating new suppliers on reliability, lead times, support responsiveness, and their ability to help manage reorder cycles and status updates. In a crossŌĆæbrand automation environment, your suppliers effectively become part of your compatibility strategy.

ISA notes that the primary drivers for migrations and upgrades are lifeŌĆæcycle and reliability risks: aging boards, failing chips, lack of spares, and increasing outages. In a crossŌĆæbrand environment, you need to manage this risk across multiple vendors. Selecting platforms with clear support guarantees and life expectations on the order of fifteen to twenty years, and avoiding architectures that vendors are about to retire, is essential.

Independent system integrators can help here. ISA recommends using them to assess products and migration paths objectively, filter vendor hype (especially around boltŌĆæon crossŌĆæplatform solutions), and share patterns from both successful and failed projects. In a mixedŌĆæbrand environment, that crossŌĆæplatform experience is one of the most valuable assets you can buy.

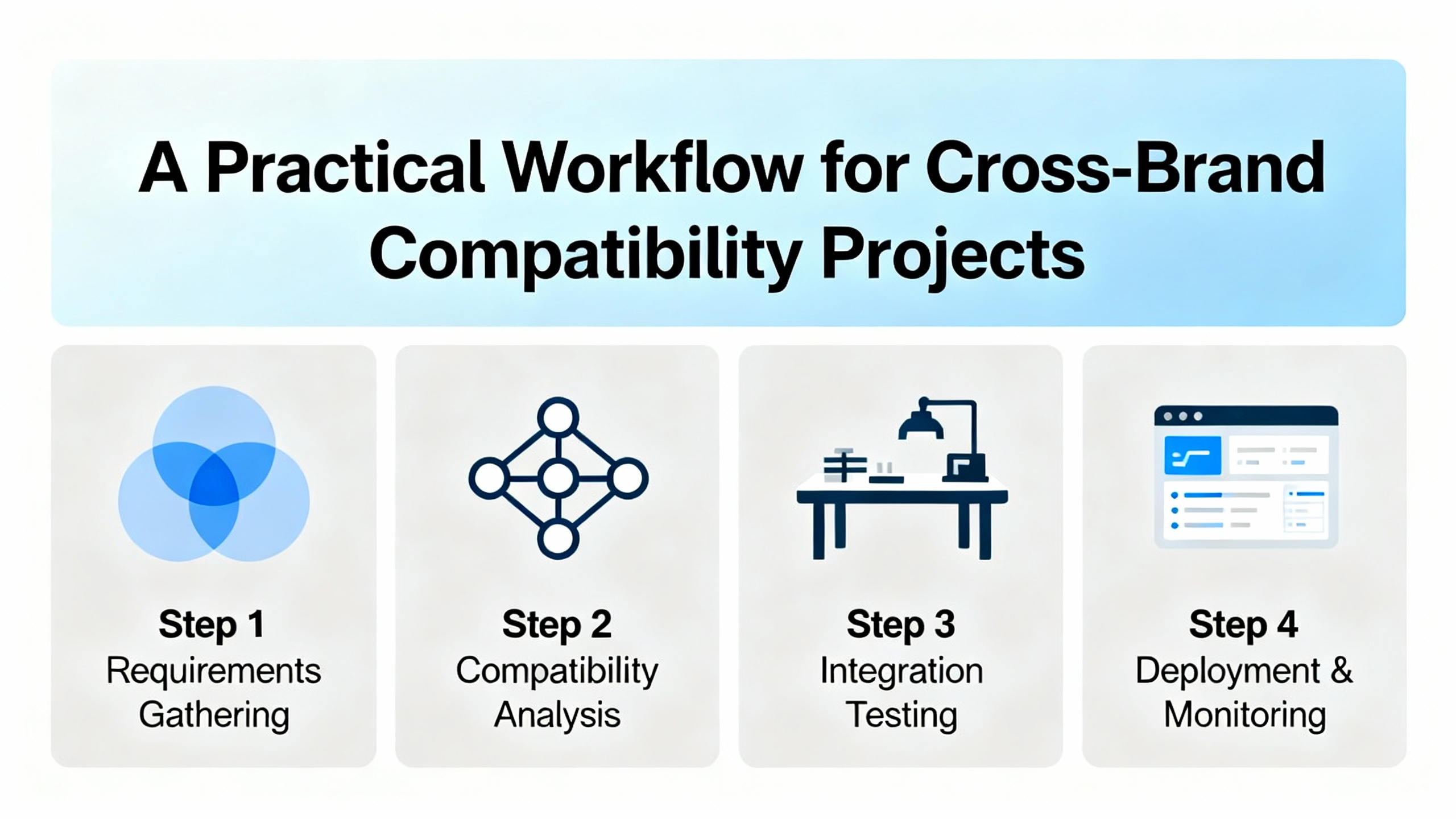

Before you start swapping components, define the end state. ISA suggests framing projects around questions such as desired endŌĆæstate functionality, cost posture, operator experience, and schedule constraints. Do you need smart I/O, advanced process control, or better enterprise connectivity? Are you trying to minimize spend while maintaining risk, or are you willing to invest for performance improvements? Are you operating on a tight planned shutdown window or dealing with an emergencyŌĆædriven cutover?

Answering these questions gives you criteria for when crossŌĆæbrand substitutions or open architectures are justified and where a vendorŌĆæsupported upgrade is actually the safer option.

A consistent lesson from integration and compatibility case studies is that documentation is the cheapest risk reducer you will ever buy. The rodless cylinder project began by documenting every existing configuration: model numbers, critical dimensions, operating parameters, and interface points. A DEM Industrial article on integrating new components into existing systems emphasizes thorough assessment of current infrastructure, including interfaces, communication protocols, and hardware and software requirements, before selecting new components.

On the controls side, building integration specialists recommend instrumented flow diagrams and detailed points lists that show equipment, control devices, and both wired and network interfaces. For compressors and other utility systems, compatibility experts suggest building a baseline at installation by tracking runtime, pressure behavior, and output trends.

This detailed picture is what allows you to assess compatibility with any new brand or platform credibly.

Once you understand the installed base, perform a compatibility analysis across the layers described earlier: mechanical, electrical, control and protocol, functional, safety, and life cycle. CrossŌĆæreferencing guidance for electronic components can serve as a template here, encouraging you to distinguish between dropŌĆæin, pinŌĆætoŌĆæpin, and functionally equivalent substitutions and to identify a small set of key parameters that truly govern compatibility.

The rodless cylinder framework offers a very concrete way to approach mechanical and pneumatic compatibility: map profile dimensions, hole patterns, load paths, and bearing surfaces; analyze load distribution; check material suitability; and determine where spacers, adapter plates, or reinforcement will be needed.

On the control and protocol side, guidance from hardwareŌĆæsoftware integration articles suggests selecting standard protocols such as MQTT, Modbus, or OPC UA where possible, using middleware when necessary, and planning for realŌĆætime constraints from the start. Building integration best practices emphasize early collaboration with IT to design networks that use VLANs, quality of service policies, and security controls so that lifeŌĆæsafety and other critical traffic are protected even as you integrate multiple systems.

Different parts of your plant call for different crossŌĆæbrand strategies. For core control platforms and safety systems, it may be more appropriate to stay within a vendorŌĆÖs supported upgrade path and use open protocols at the edges. For peripheral devices, pneumatics, and mechanical elements, crossŌĆæbrand substitution with wellŌĆæengineered adapters and crossŌĆæreference validation may deliver the best mix of flexibility and cost.

Where you have deep vendor lockŌĆæin but no immediate path to a full migration, boltŌĆæon gateways may be unavoidable. ISAŌĆÖs recommendation is to treat those as temporary. Use them to bridge the gap while you design a longŌĆæterm architecture based on open standards and then phase them out as you move subsystems to the new design.

Independent system integrators can help you map these strategies to specific platforms, because they see where and how different vendorsŌĆÖ equipment actually plays well together in the field.

Testing is where compatibility becomes more than a design exercise. The rodless cylinder case study stresses controlled implementation and validation, including detailed installation procedures, leak testing, alignment verification, and performance testing under the full pressure and flow range and dynamic operation. Hardware integration experts recommend hardwareŌĆæinŌĆætheŌĆæloop simulations and iterative testing to catch timing and communication issues early.

ISA warns that skipping network capacity studies and validation can lead to crashes during cutover, especially when old and new HMIs are run in parallel. Building integration guidance similarly warns against connecting islanded subsystems without careful planning because troubleshooting becomes harder when data is scattered.

The principle is straightforward: assume nothing and test everything under conditions that resemble real operation as closely as possible before you rely on a crossŌĆæbrand combination for production.

Compatibility projects fail as often on the human and organizational side as on the technical side. The compressor brandŌĆæswitching guide argues for planning holistically across engineering, operations, training, inventory, warranty, and supply chain to reduce risk. DEM IndustrialŌĆÖs integration guidance recommends a structured integration plan with clear stages, timeline, resource allocation, and risk and contingency measures.

On the automation side, that means coordinating with maintenance teams on new spareŌĆæparts strategies, training operators and technicians on new HMIs and diagnostics, aligning with purchasing on vendor performance expectations, and updating preventive maintenance programs to reflect the behavior and wear patterns of new brands.

Standardization is how crossŌĆæbrand compatibility stops being a oneŌĆæoff project and becomes part of how your plant operates. Calvary Robotics defines standardization as establishing uniform protocols, guidelines, specifications, and performance criteria so automated elements are compatible, reliable, and interoperable. They emphasize benefits such as consistency, efficiency, scalability, and cost savings, as well as the need for KPIs and structured change management to maintain and improve standards over time.

The rodless cylinder project illustrates this. The real payoff did not come just from designing adapters; it came from turning those designs into standards, complete with asŌĆæbuilt drawings, parts lists, installation procedures, performance expectations, and verification protocols. That allowed the organization to treat mixedŌĆæbrand assets as a single, unified platform with predictable behavior and measurable ROI, which the author reports often falls into a sixŌĆæ to twelveŌĆæmonth window for multiŌĆæbrand compatibility initiatives when executed well.

By defining technical standards, documentation expectations, and metrics for availability, maintenance cost, and inventory, you create a feedback loop that allows you to refine your crossŌĆæbrand strategy rather than reinvent it with each project.

In many cases, yes for the control core and safety systems, but not at the expense of pragmatic crossŌĆæbrand strategies around them. ISAŌĆÖs experience with multigenerational upgrade paths shows that choosing a coherent control platform with a clear support roadmap makes longŌĆæterm planning much easier. Around that core, it is realistic and often beneficial to support multiple brands for actuators, sensors, and pneumatics, provided you treat interfaces and crossŌĆæreferencing systematically and document your standards.

They are acceptable as interim tools and migration aids, not as permanent architecture. ISA explicitly recommends treating crossŌĆæplatform boltŌĆæons as temporary bandŌĆæaids. Use them to bridge legacy systems while you design and implement an architecture based on open protocols and clean integration points, and plan to retire them as you complete migrations.

Use the kind of numbers that real projects report. The rodless cylinder case study shows a 42% reduction in unique spare parts, a 78% reduction in emergency orders, a 73% decrease in average replacement time, and a 23% reduction in annual maintenance costs after implementing a crossŌĆæbrand interface standard. Building integration studies report substantial cable and infrastructure savings from integrated designs. When you frame compatibility work as a way to cut downtime, inventory, and maintenance cost rather than as an engineering preference, it becomes far easier to secure support.

In the field, when a line is down and the only available component carries a different logo than the original, you quickly find out whether you have a compatibility strategy or a compatibility problem. Treat crossŌĆæbrand integration as a deliberate discipline, grounded in standards, testing, and documented practice, and your plant will be ready long before that moment arrives.

Leave Your Comment