-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

If you are responsible for keeping a line running, you do not care whether a failure comes from a weak relay contact or a cheap hydraulic fitting. You care that the machine is down, operators are waiting, and every minute of idle time is burning money. The choice between original equipment manufacturer (OEM) parts and third-party or aftermarket parts sits right in the middle of that reality.

Most published comparisons of OEM and aftermarket parts come from automotive and heavy equipment repair. Sources like NerdWallet, Thompson Tractor, Titan Machinery, and several dealer service centers all describe the same basic trade-off: OEM parts favor predictable quality and fit, while aftermarket parts favor lower price and wider choice, with more variation in quality. Those themes translate directly into factory automation, even if our components are PLC I/O cards, drives, encoders, and HMI panels instead of brake pads and bumpers.

As a controls engineer or maintenance lead, you do not need marketing language; you need a clear way to decide when to stay with OEM and when a third-party part is an acceptable, or even better, choice. This guide walks through that decision using real-world evidence from those sources, then reframes it for industrial automation and control systems.

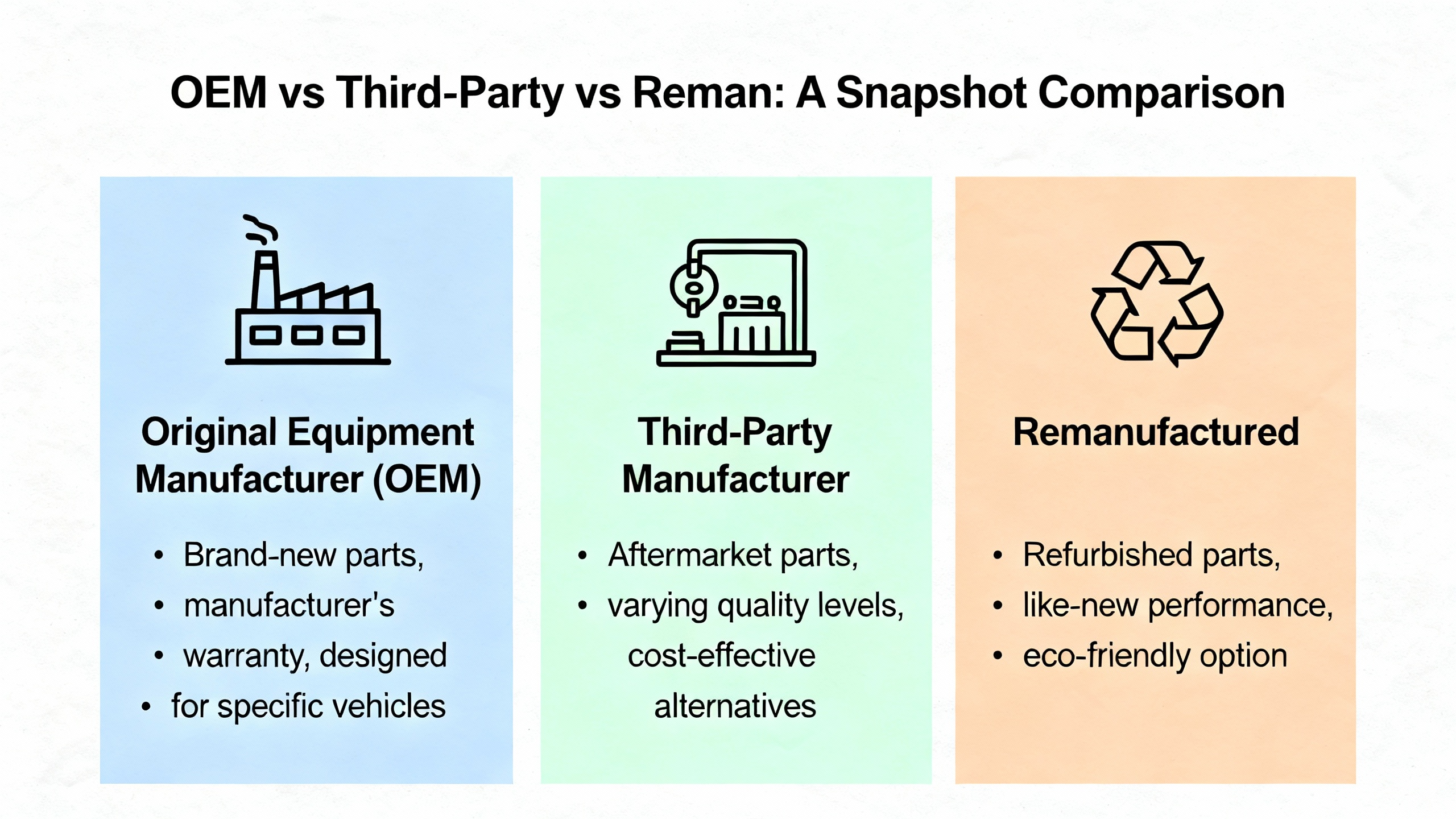

Different industries use slightly different labels, but the underlying ideas are consistent.

Genuine parts are what left the factory with the machine or vehicle. NerdWallet describes these as the components installed at the assembly line. In practice, most of us only encounter ŌĆ£genuineŌĆØ as a branding term on packaging or dealer quotes.

OEM parts are built by the same manufacturer that designed the original component or by a supplier working to that manufacturerŌĆÖs exact specification. Automotive repair articles from Auto Works in Woodbury, Huron Automotive, Suburban Collection, and others all stress that OEM parts are dimensionally correct for that make and model, engineered to match the original performance, and validated by the original makerŌĆÖs test regime.

Aftermarket or third-party parts are built by companies that are not the original machine builder. Auto training material, dealership blogs, and equipment dealers like Thompson Tractor describe these parts as designed to fit and function like OEM pieces but without the original brand on the box. They range from low-cost substitutes to high-end upgrades.

Titan Machinery also introduces a fourth category in heavy equipment: remanufactured parts. Their CNH Reman program takes used assemblies, rebuilds them to original spec, and often adds design improvements, then backs them with a strong warranty. In industrial automation, remanufactured drives and servo motors play a similar role.

For control systems, you can map this terminology as follows. A drive module from the same vendor that built your machineŌĆÖs control cabinet is OEM. A mechanically compatible module from another manufacturer that claims to plug into the same rack or bus is a third-party part. A drive rebuilt by a specialist and returned with test documents and warranty is a reman option.

The labels are less important than the engineering behind them. What matters is fit, reliability, and how much risk you are willing to carry in exchange for price and availability.

Most marketing copy claims that OEM and aftermarket parts are ŌĆ£the same, just cheaper.ŌĆØ Actual field experience says otherwise, and this is where the decision starts to look less theoretical.

A former BMW dealer technician writing on diag.net reports over two decades of experience with genuine BMW parts and notes almost no failures of new genuine parts within the typical twoŌĆæyear warranty window. In that environment, the effective failure rate felt close to zero in day-to-day work.

When that technician later ran an independent shop that relied on non-genuine OEM and aftermarket components for cost reasons, the story changed. Based on the shopŌĆÖs own repair records, they estimated that the supposedly equivalent OEM-branded parts had failure rates on the order of half of the units over two to three years, in stark contrast to the genuine parts. The authorŌĆÖs conclusion is blunt: the industry claim that OEM-labeled parts are simply genuine parts without the logo did not match their experience.

It is important to keep the scope honest. Those numbers come from one shop, one brand, and one segment of the market. They are not universal statistics for every OEM or every third-party maker. But they are a concrete reminder that the label ŌĆ£OEMŌĆØ does not guarantee the same quality level as the genuine part, and that third-party failure rates can be dramatically different depending on where you buy.

Multiple other sources echo the pattern qualitatively. Collision repair shops such as Conestoga Collision and Freedom Collision emphasize that OEM parts tend to show more consistent quality and fit, while aftermarket quality ranges from excellent to unacceptable. Heavy-equipment dealers like Titan Machinery and Thompson Tractor make the same point: OEM parts are engineered for the exact machine and tested accordingly; aftermarket parts can be very good, but they are not held to the OEMŌĆÖs internal acceptance criteria unless the supplier chooses to match them.

Several service centers, including Huron Automotive and Suburban Collection, highlight a few reasons why OEM parts are more predictable.

They are built from materials chosen and validated by the original engineering team for durability, performance, and integration with the rest of the system.

They follow the same specifications used for assembly-line parts, which reduces the chance of unexpected behavior.

The part designs are tightly tied to safety, emissions, and regulatory compliance, which discourages cutting corners.

For an automation engineer, this translates directly. A drive module or safety relay from the control-system OEM is likely to have been validated as part of the overall system, including thermal performance inside a crowded cabinet and interaction with the rest of the safety chain.

The BMW technician on diag.net proposes an interesting theory to explain why genuine, OEM, and cheaper aftermarket parts feel different in practice. In their view, parts produced on the same manufacturing line might be sorted by tolerance. Units that hit the tightest specification window go into genuine-branded boxes. Units that are slightly outside that band, but still acceptable for operation, become OEM-branded parts sold through other channels. Components that drift further from nominal may be repackaged as low-cost aftermarket products.

The author is careful to call this a theory, not a documented fact, and notes that no one in the supply chain has formally confirmed it. Still, it fits the observed pattern in their shop, where genuine parts performed very consistently, OEM parts had visible peaks and troughs in quality over time, and budget aftermarket components were treated as a last resort.

You do not have to accept that theory literally to see the lesson for industrial automation. The tighter the control on manufacturing tolerances and testing, the fewer surprises you will face when you power up the line after a repair. OEM channels generally enforce those controls more strictly than the commodity end of the aftermarket.

Fit is not only about the bolt pattern or connector layout. It is about how the part interacts with sensors, firmware, communication buses, and safety functions.

Automotive sources converge on the same point. Huron Automotive and Valley Ford stress that OEM parts are engineered specifically for a given model, which helps avoid rattles, misalignment, leaks, and odd behaviors. Freedom Collision underlines that in collision repair, precise fit affects airbag timing, crumple-zone performance, and even the alignment of advanced driver assistance sensors. Thompson Tractor and Titan Machinery make similar points for equipment parts, warning that misalignment from off-brand components can increase wear on surrounding parts and shorten overall machine life.

If you translate that to automation, a third-party encoder that physically mounts correctly but delivers slightly different signal timing can cause miscounts or nuisance faults in the PLC. A replacement HMI with unofficial drivers might display data correctly but mishandle alarm acknowledgments. A cost-cutting power supply that meets nominal voltage but has worse transient behavior can create intermittent issues that are extremely hard to trace.

OEM parts reduce these risks because they are validated as part of the complete system. High-quality third-party parts can also integrate well, but you have to verify that integration yourself instead of relying on the original machine builderŌĆÖs engineering sign-off.

The warranty question is where many maintenance teams feel trapped: use OEM parts and pay more, or accept the risk that a third-party component might complicate claims.

NerdWallet explains that, in the context of vehicles, simply choosing an aftermarket part does not automatically void a warranty under U.S. federal law. However, if a failure is traced directly to that aftermarket part, the manufacturer can deny coverage for that specific repair. On the other hand, several service centers, including Huron Automotive and Valley Ford, point out that some warranties and service plans explicitly require OEM parts for covered repairs, especially for critical systems, and that using third-party parts can limit what the manufacturer will pay for.

These positions are not contradictory. Together, they mean you need to read the actual warranty or service contract. The fine print decides whether the issue is strict OEM-only coverage, or a more limited exclusion when an aftermarket part causes damage.

In industrial automation, service contracts and extended warranties for equipment follow the same logic even if the legal framework is different. Many OEMs insist on their own parts for covered work and reserve the right to decline responsibility when unsupported third-party components are installed. That does not mean you can never use third-party parts; it means you should be intentional about when you are stepping outside the OEMŌĆÖs supported configuration.

Several automotive and collision-repair sources draw a sharp line between safety-critical and non-critical parts. Huron Automotive calls OEM parts non-negotiable for systems like brakes, airbags, steering, and structural panels because those components are validated against crash and safety standards. Freedom Collision emphasizes that poorly fitting aftermarket body parts can disrupt crumple zones, weaken structural integrity, and interfere with collision-avoidance sensors.

Preston Hood and Conestoga Collision echo the same recommendation in collision repair: use OEM parts when the repair touches safety, structure, or key systems; consider aftermarket for cosmetic or non-critical pieces where the impact of failure is lower.

For factory automation, that distinction is just as important. A safety relay, light curtain, or interlock switch sits in the same category as an airbag module or brake caliper. A third-party replacement might work perfectly, but if it has not been evaluated as part of your machineŌĆÖs safety design, you are accepting extra risk. Indicator lamps, enclosure hardware, and non-critical panel accessories are closer to cosmetic body parts; the risk of using reputable third-party alternatives is narrower.

Most of the pressure toward third-party parts comes from budgets and schedules. Several sources, from Auto Training resources to Whitten Brothers and Valley Ford, note that OEM parts generally cost more than aftermarket alternatives. Titan Machinery and Thompson Tractor both highlight that lower upfront cost does not always mean lower total cost of ownership.

Third-party parts often win on initial price and availability. Aftermarket components are designed for broader compatibility, which makes it easier for distributors and online sellers to stock them. Whitten Brothers points out that consumers see more choices and faster access to aftermarket parts, while OEM parts may require ordering directly through dealerships, with longer lead times and fewer options.

In industrial settings, this mirrors the everyday experience of calling the machine builder and hearing about a several-week lead time for a specific module while a third-party vendor can ship a compatible part in a day. For high-volume plants, the cost of a week of downtime can dwarf the price difference between OEM and third-party.

The key is to look beyond the price tag and ask what happens if the replacement fails early or does not integrate cleanly. Titan Machinery frames this as a tradeoff between cheaper, potentially shorter-lived parts and more expensive OEM parts that support higher uptime, longer life, and better warranty backing. Thompson Tractor recommends evaluating total cost, not just purchase price, including downtime, extra labor for adjustments, and the impact of any secondary damage caused by marginal components.

Bringing those themes into a controls and automation context, you can sketch a practical rule of thumb without inventing new statistics.

OEM parts make sense when the component is safety-critical or directly tied to machine safety performance. Automotive and collision-repair sources are unambiguous about this for brakes, airbag systems, and structural panels. The automation parallel would be safety relays, emergency-stop circuits, safety PLC modules, and guarding systems where failure directly affects operator safety.

They are also the safer choice when the equipment is under warranty or covered by a service agreement that references OEM components. The vehicle-repair sources highlight that OEM usage often preserves warranty coverage, while third-party parts can limit it. For expensive automation assets, the same logic applies: if a drive, controller, or HMI fails under warranty, using OEM hardware keeps the conversation straightforward with the manufacturer.

OEM is preferable when the component is deeply integrated with proprietary firmware, protocols, or configuration tools. Many dealership and manufacturer guides stress that OEM electronic modules are tuned to work seamlessly with the rest of the system and that aftermarket modules may not behave exactly the same way. For controls, this includes main PLC CPUs, integrated motion controllers, and communication modules.

Finally, OEM parts are often the better choice when the cost of a future failure is unacceptably high. The BMW technicianŌĆÖs experience, combined with dealer and equipment-dealer guidance, suggests that genuine or OEM parts provide a more stable quality baseline. For a production line where unplanned downtime costs thousands of dollars per hour, paying more to reduce the probability of surprises can be a rational decision.

The other side of the decision is not ŌĆ£OEM or disaster.ŌĆØ Properly chosen third-party parts can be a smart, disciplined choice, and several sources highlight when that is true.

NerdWallet notes that for drivers on tight budgets, using reasonably chosen aftermarket parts is better than postponing necessary repairs, because delayed maintenance can cause more damage and higher costs later. That logic holds in automation. If the choice is between installing a reputable third-party component now or running a machine with a known defect while waiting for OEM stock, the third-party option may be the safer path.

Quora contributors with technical backgrounds emphasize that aftermarket manufacturers can innovate faster than OEMs. They are not locked into keeping older designs alive for long periods, so they can release updated components with improved materials or performance. The example given is brake pads and shocks, where aftermarket brands offer multiple grades tailored for different performance and comfort levels, while OEMs may offer only a single spec tuned for a new vehicle.

In an automation context, this could resemble a third-party sensor with better environmental protection or a replacement drive that incorporates more modern control algorithms while remaining compatible at the I/O level. You still need to validate that integration, but the idea that aftermarket equates only to low-end quality is too simple.

Several dealership and collision-repair articles, including guidance from Auto Training resources, Conestoga Collision, and Whitten Brothers, endorse aftermarket parts for non-critical repairs or cosmetic items, provided the buyer invests time in researching brands and specifications. In other words, third-party parts are not automatically inferior; they simply require more diligence.

Finally, Titan Machinery highlights another role for non-genuine options: short-term or budget-constrained repairs. They position aftermarket parts as acceptable when you need a fast, lower-cost fix, while encouraging OEM or reman parts when the goal is maximum uptime and long-term reliability. For a plant, that can be a realistic strategy: use a third-party component to get through a peak production period, then schedule an OEM swap during a planned shutdown.

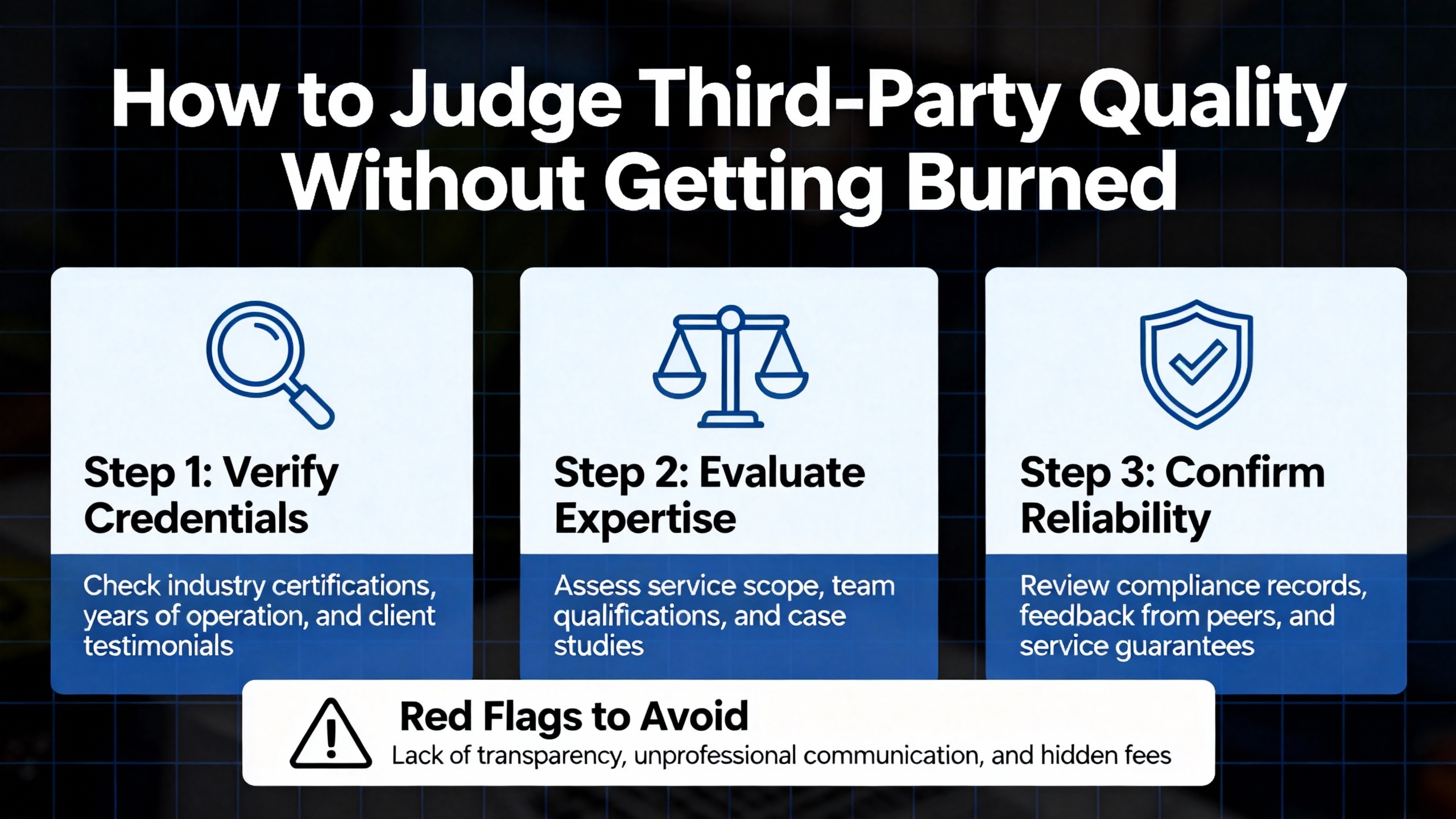

The biggest risk with third-party parts is not that they are all bad; it is that their quality varies much more than OEM parts. Across sources, a few practical checks show up repeatedly.

Several guides by Freedom Collision, Thompson Tractor, and NerdWallet recommend researching the manufacturerŌĆÖs reputation rather than treating all aftermarket brands as equivalent. High-end suppliers often meet or exceed OEM standards, while house brands targeting the lowest price may only just meet basic specs and degrade faster, as the Quora discussion notes.

Warranty backing is another clear signal. OEM parts commonly carry at least a oneŌĆæyear warranty according to multiple dealership and repair articles, and Titan Machinery mentions twelve months of coverage when their technicians install OEM parts, with reman components often backed for up to twenty-four months. Many low-cost aftermarket parts offer limited or no warranty. That does not prove quality by itself, but a meaningful warranty shows that the manufacturer is willing to share some of the risk.

Fitment and compatibility deserve deliberate checks. Automotive sources describe issues ranging from misaligned body panels to gaps in mounting surfaces that lead to noise and premature wear. In controls, this translates to verifying electrical ratings, communication protocols, and mechanical interfaces rather than assuming ŌĆ£close enoughŌĆØ will work. When in doubt, consulting a trusted service partner, as many of the dealership and collision shops advise, is preferable to guessing from a catalog.

Finally, be wary of claims that third-party parts are ŌĆ£identical to OEMŌĆØ without solid evidence. The BMW technicianŌĆÖs experience strongly challenges that slogan, at least in their domain. Instead of relying on labels, treat each third-party part as a proposal: what evidence is there for its quality, integration, and support, and does that evidence meet the risk level you can tolerate?

The table below condenses the recurring patterns from the automotive and heavy-equipment sources, reframed for general equipment and automation decisions.

| Dimension | OEM / Genuine | Third-Party / Aftermarket | Remanufactured (per Titan Machinery) |

|---|---|---|---|

| Design and spec | Built to original spec for specific machine or model | Designed for broad compatibility; spec varies by brand | Based on original design, rebuilt to original or improved spec |

| Quality consistency | Generally high and predictable across units | Ranges from premium to poor; requires brand-by-brand judgment | Validated against original performance targets |

| Fit and integration | Exact fit; validated as part of full system | May need adjustments; risk of misfit or subtle incompatibility | Built to fit and function as the original assembly |

| Warranty | Commonly around one year or more from manufacturer | Often limited or none; varies widely | Often equal or better than OEM, sometimes up to two years |

| Price | Higher upfront cost | Lower purchase price, especially at low end | Between OEM and aftermarket; can be attractive for assemblies |

| Best use cases | Safety-critical, under warranty, high cost of failure | Budget-limited, non-critical, or where a vetted upgrade exists | High-value components where new OEM is very expensive |

The exact numbers and policies differ between vendors and industries, but the shape of the trade-off is consistent.

Consumer guidance from NerdWallet explains that, for vehicles, simply installing an aftermarket part does not automatically cancel a warranty. However, if that part directly causes a failure, the manufacturer can deny coverage for that repair. Several dealership and repair sources add that some service plans specify OEM parts for covered work. In practice, for both vehicles and industrial equipment, the safest approach is to read the actual warranty or service contract and assume that unsupported third-party parts may complicate future claims.

The pattern across sources is that OEM and genuine parts are more consistent, not that every third-party part is inferior. The BMW technicianŌĆÖs experience on diag.net shows genuine parts performing far better than non-genuine OEM-labeled parts in their specific context, and collision-repair and equipment dealers repeatedly warn about low-end aftermarket components. At the same time, the Quora discussion and some equipment dealers acknowledge that reputable aftermarket brands can match or exceed OEM performance. The gap is really between well-engineered, well-supported parts and those built mainly to hit the lowest price point.

Most sources focus on specific parts rather than entire systems, but a common theme is that safety-critical and highly integrated components should favor OEM or OEM-equivalent quality, while non-critical or cosmetic parts can tolerate more flexibility. In an automation system, that suggests a mixed approach: keep core safety, control, and communication modules aligned with the OEM or a carefully vetted equivalent, but use trusted third-party options for accessories, simple sensing, or standardized hardware where the consequences of a failure are limited and easy to manage.

On the plant floor, the OEM versus third-party question is not about ideology; it is about risk, cost, and uptime. The evidence from automotive repair shops, collision centers, equipment dealers, and experienced technicians points in the same direction: OEM channels deliver more predictable quality and integration, while third-party parts offer price and availability at the cost of greater variation. If you treat each component decision as a risk trade, keep OEM for safety-critical and high-consequence roles, and reserve vetted third-party options for the right situations, you can keep your lines running without paying for brand names where they do not earn their keep.

Leave Your Comment