-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When you spend your days around PLCs, MCC rooms, and production lines, you learn quickly that a ŌĆ£trueŌĆØ emergency shutdown is almost never just bad luck. In most cases the plant has been telling you something for weeks: vibration creeping up on a fan bearing, more nuisance alarms on a transfer pump, a bypassed interlock that never made it back into service. By the time the emergency stop is hit, you are already paying for a long chain of small decisions.

This article looks at plant emergency shutdown prevention from two angles that have to work together: proactive maintenance that keeps you away from the edge in the first place, and rapid, disciplined response when you do have to bring the plant down fast. The perspective is that of an automation engineer on site, tying together safety systems, maintenance programs, and real-world operating practices, with support from industry guidance by organizations such as Alltracon, Plant Engineering, OSHA, the Chemical Safety Board, and others.

Across industrial manufacturing, power, and process facilities, shutdowns fall into two basic categories. Planned shutdowns or turnarounds are scheduled pauses in production used to carry out maintenance, inspections, repairs, and upgrades that cannot be done safely during normal operation. Sources such as BES Group, BLJ In-situ Solutions, and Bolton Holdings describe these events as large, complex projects that are essential for asset reliability and regulatory compliance, but also expensive and highly disruptive if poorly managed.

Emergency shutdowns are different in both intent and dynamics. Alltracon defines an emergency shutdown as a formal protocol to rapidly halt operations in hazardous situations such as serious equipment failures, safety breaches, or natural disasters. The goal is to prevent injury and further damage by stopping the process immediately, often via automated emergency shutdown systems or hardwired emergency stop devices. In these events, the plant is no longer controlling the timing; the incident is.

Several sources point out that unplanned and emergency outages typically carry far higher direct and indirect costs than planned downtime. Quality Millwright notes that emergency repairs can cost up to roughly five times more than planned work once you include overtime, rush parts, and lost production. Fess Group frames planned downtime as a deliberate investment in reliability that reduces the probability and impact of future unplanned downtime.

From an automation and controls standpoint, that difference shows up in how your systems are used. During a planned shutdown, the PLC or DCS follows a carefully written sequence and lockout/tagout (LOTO) procedures are in place before work begins. During an emergency shutdown, the safety layer overrides production logic and forces equipment to a safe state, sometimes in seconds. If you want to prevent emergency events, you have to build disciplined, data-driven behavior around the slower, planned side of that equation.

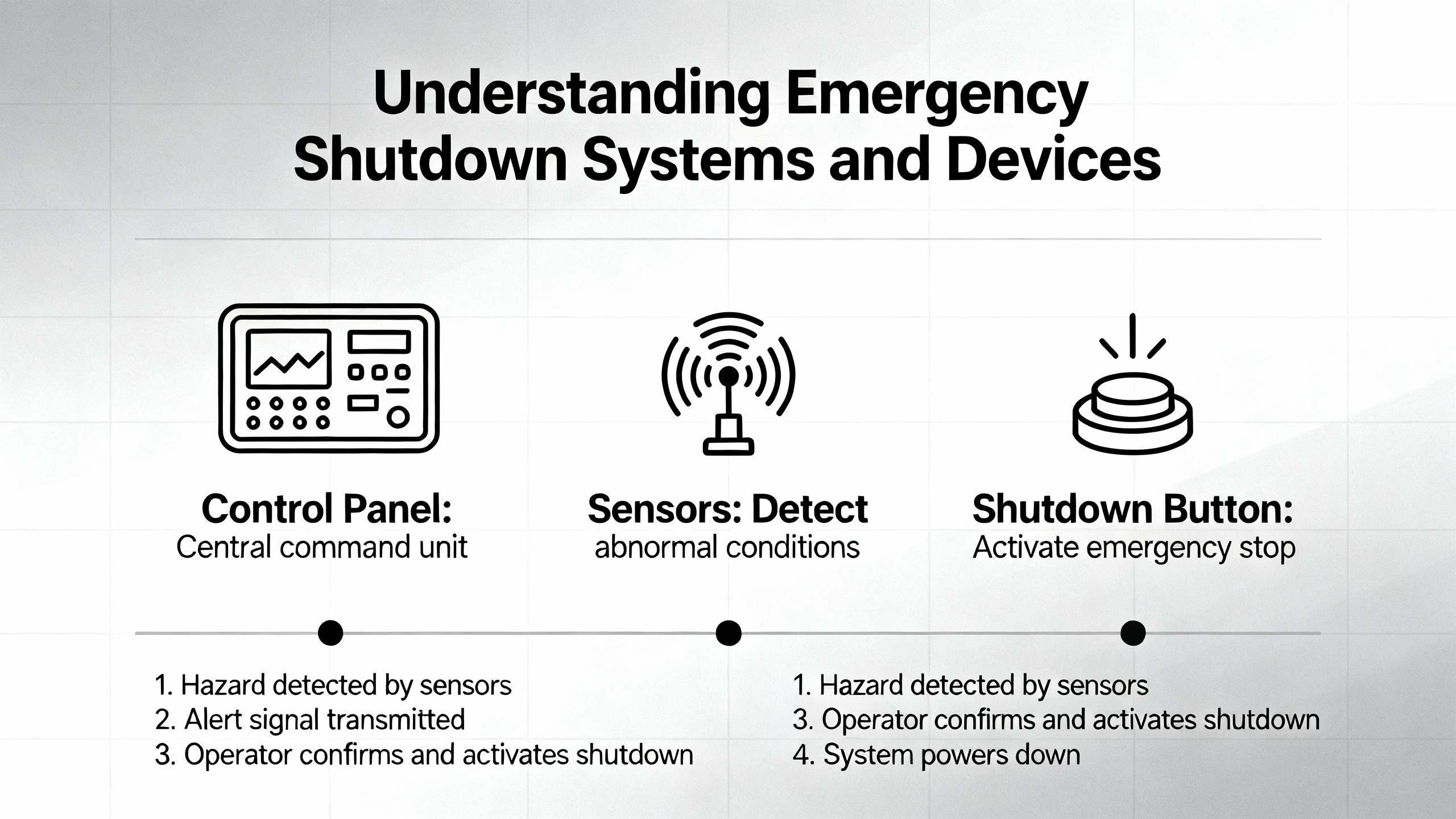

Emergency shutdown in a modern plant is not just a big red button. It is a layered combination of procedures, safety-rated hardware, and automation logic.

At the most visible level, you have emergency stop (EŌĆæstop) switches. According to EŌĆæSwitch, an emergency stop switch is a safety mechanism designed to rapidly shut down machinery when normal shutdown methods are not fast or reliable enough. The typical actuator is a large, red, mushroom-head button located near the hazard; when pressed, it mechanically latches and opens the control circuit so power to motors or other critical components is removed. Many designs use pushŌĆælock and twistŌĆætoŌĆærelease actions and incorporate normally closed safety contacts wired in series with other safety devices.

These devices have concrete advantages. They give operators and maintenance technicians a last line of defense, they can be actuated under stress, and they align with safety expectations from OSHA, NFPA, and ANSI for industrial machinery. EŌĆæSwitch also notes the trade-offs: unintended activation can create unplanned downtime, and mandatory manual reset before restart can slow production if operators use EŌĆæstops casually instead of standard stop commands. That is a behavioral and training issue more than an equipment problem.

Above the device level, emergency shutdown systems in process plants go further. Alltracon emphasizes the need for automated shutdown technologies that can isolate affected systems, shut valves, trip drives, and secure hazardous materials without relying solely on human reaction time. Data logging and real-time monitoring of temperature, pressure, and flow are highlighted as critical inputs that allow these systems to detect abnormal conditions early and support both shutdown and recovery decisions.

From a control-system perspective, that means your PLC or safety controller should not only execute emergency sequences but also provide clear, unambiguous status: which interlock tripped, which line isolated, which devices failed to respond. Without that feedback, rapid response turns into guesswork in the control room.

If you want to prevent emergency shutdowns, you have to be honest about why they happen. Plant Engineering points out that unplanned shutdowns rarely come from a single random failure. Typical root causes include design flaws, poor installation, operating equipment outside its limits, inadequate training, and chronic underinvestment in preventive maintenance. The same source cites an estimate that human error contributes to roughly 80% of equipment failures, which matches what many of us see in failure investigations.

Bolton Holdings and Reliable Plant both emphasize project and risk-management factors that set the stage for trouble. When shutdown-related work is crammed into short windows without realistic schedules, adequate resourcing, or clear roles, the plant inherits hidden risks that later show up as leaks, trips, or failures during restart. CRB Group adds that incomplete vendor documentation and missing calibration records can stall commissioning and validation, especially in regulated industries, and directly delay safe startup.

On the safety side, the Chemical Safety Board and Alltracon highlight that startup and shutdown phases are among the most hazardous periods of a plantŌĆÖs lifecycle. Non-routine work, bypassed safeguards, and changing process conditions all multiply risk. If these phases are not treated as formal, high-risk operations, the probability of an emergency event increases, regardless of how good the equipment is.

When you connect these points to the control-room reality, a familiar picture emerges. Operators are pushed to run closer to capacity, alarms are normalized, preventive work is deferred to ŌĆ£the next outage,ŌĆØ and control changes are implemented without full management-of-change discipline. The emergency shutdown is then blamed on the visible trigger, not on the pipeline of decisions and omissions that made the plant fragile.

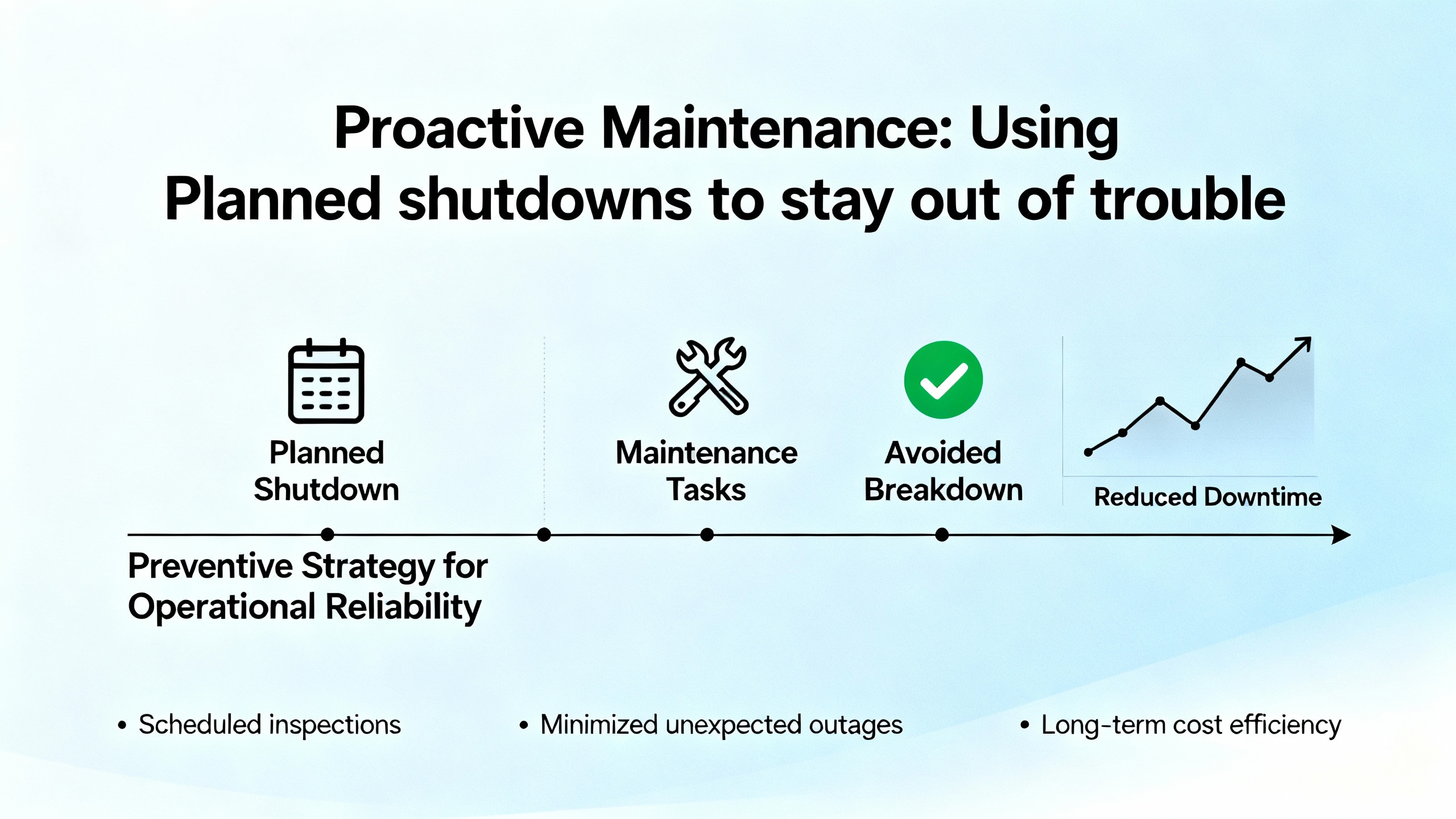

Preventing emergency shutdowns starts with making planned downtime do its job. Multiple sources, including Alltracon, TriMedia, BES Group, BLJ In-situ Solutions, Quality Millwright, F.E. Moran, and others converge on the same message: treat shutdowns as strategic maintenance and reliability projects, not as necessary evils.

BES Group and BLJ In-situ Solutions stress comprehensive planning and scheduling. Effective shutdowns begin with clear scope definition, realistic timelines, and early identification of required labor, materials, and specialist contractors. Alltracon suggests that major industrial turnarounds should start planning 12 to 18 months ahead, while TriMedia notes that even smaller plant shutdowns usually need at least three to four months of preparation to lock in contractors, parts, and safety training. In other words, the planning horizon needs to match the complexity and risk of the outage.

Quality Millwright offers a useful framing of preventive shutdowns as the industrial equivalent of an annual checkup. The article explains that preventive shutdowns are planned halts in production used to perform inspections, maintenance, and upgrades before things fail, involving coordinated work across electrical, mechanical, millwright, and fabrication crews. During these outages, technicians can inspect and replace bearings, refresh mechanical seals, clean and lubricate gearboxes, rebalance turbines and compressors, and test electrical systems for load integrity. Done systematically, this reduces mechanical stress, extends equipment life, and decreases emergency repairs.

F.E. Moran adds another dimension in high-pressure piping environments. They highlight pre-shutdown inspections, critical piping and equipment replacements, non-destructive examination, and post-turnaround testing as core elements of shutdown execution. Advanced prefabrication and disciplined project management are presented as tools to compress outage duration without sacrificing quality, which is important for facilities that cannot afford extended downtime.

Plant Engineering connects these mechanical and project practices with a reliability-centered approach. The article recommends predictive and condition-monitoring technologies such as vibration analysis, oil analysis, infrared thermography, ultrasound, and efficiency monitoring, as well as historian systems like DeltaV, Matrikon, and Pi. Combined with metrics such as overall equipment effectiveness, preventive-maintenance compliance, mean time between failures, and total cost of ownership, these data streams allow plants to move from reactive repairs to data-driven decisions about when to intervene.

A case study from the same source illustrates how structured reliability work can double mean time between failures on a problematic conveyor, while also raising preventive-maintenance compliance and reducing costs. While every site is different, the principle is consistent: use planned shutdowns and predictive data to break recurring failure cycles, so the plant is less likely to hit the emergency stop later.

Emergency shutdown prevention is not just about avoiding failures; it is also about ensuring that when you do stop the plant, nobody is injured in the process. Here, OSHA requirements and industry best practices are clear.

Alltracon, ProcessBarron, Safex, NMCCat, Tool4pro, and others all emphasize rigorous pre-shutdown risk assessments. The hazards to consider include electrical systems, hazardous materials, confined spaces, work at height, high-pressure lines, and stored energy. Safex describes safe shutdown and startup as safety-critical processes that require structured planning, formal procedures, and clear roles and responsibilities. NMCCat advises beginning shutdown planning several months in advance, conducting comprehensive risk assessments, and anticipating potential hazards so they can be avoided rather than merely reacted to.

Lockout/tagout is central in this picture. ProcessBarron, Alltracon, NMCCat, Safex, and Tool4pro highlight the need to isolate all energy sourcesŌĆöelectrical, mechanical, hydraulic, pneumatic, thermalŌĆöbefore maintenance work begins. That includes shutting down and verifying zero energy, applying approved locks and tags, and ensuring each worker attaches a personal lock so equipment cannot be re-energized until every worker is clear. Safex points out that part of pre-shutdown planning is making sure emergency procedures, first-aid and fire plans, and the location of safety equipment are clearly understood by everyone.

Confined-space and work-at-height safety appear repeatedly in the safety-focused sources. AlltraconŌĆÖs safety protocols article and ProcessBarronŌĆÖs shutdown safety guidance both underline that confined-space entry requires permits, continuous atmospheric monitoring, and adherence to OSHA rules, while work at height demands trained personnel, appropriate fall protection, and supervision by qualified individuals. Tool4pro reinforces this by recommending formal work permits for high-risk tasks, plus preliminary risk assessments and last-minute worker-initiated risk checks to account for changing site conditions.

Housekeeping is another recurring theme. NMCCat and Safex describe clean, organized work areas as essential for avoiding slips, trips, and blocked access to emergency equipment. Vector Solutions, in its manufacturing safety guidance, supports this by noting that slips, trips, and falls are among the most common industrial injuries. Good housekeeping is not a cosmetic issue; during shutdowns and restarts, when equipment is open, cables are everywhere, and crews are under time pressure, clean floors and clear paths are safety controls.

From an automation engineerŌĆÖs seat, this has direct implications. When developing shutdown and startup sequences in PLC or DCS logic, you must assume that physical LOTO, permits, and inspections are in place and working as designed. Your logic can mitigate risk with interlocks, permissives, and startup checks, but it cannot compensate for a missing lock, an open blind, or a blocked emergency exit. The culture around safety protocols and energy control has to be strong before the control system can do its part.

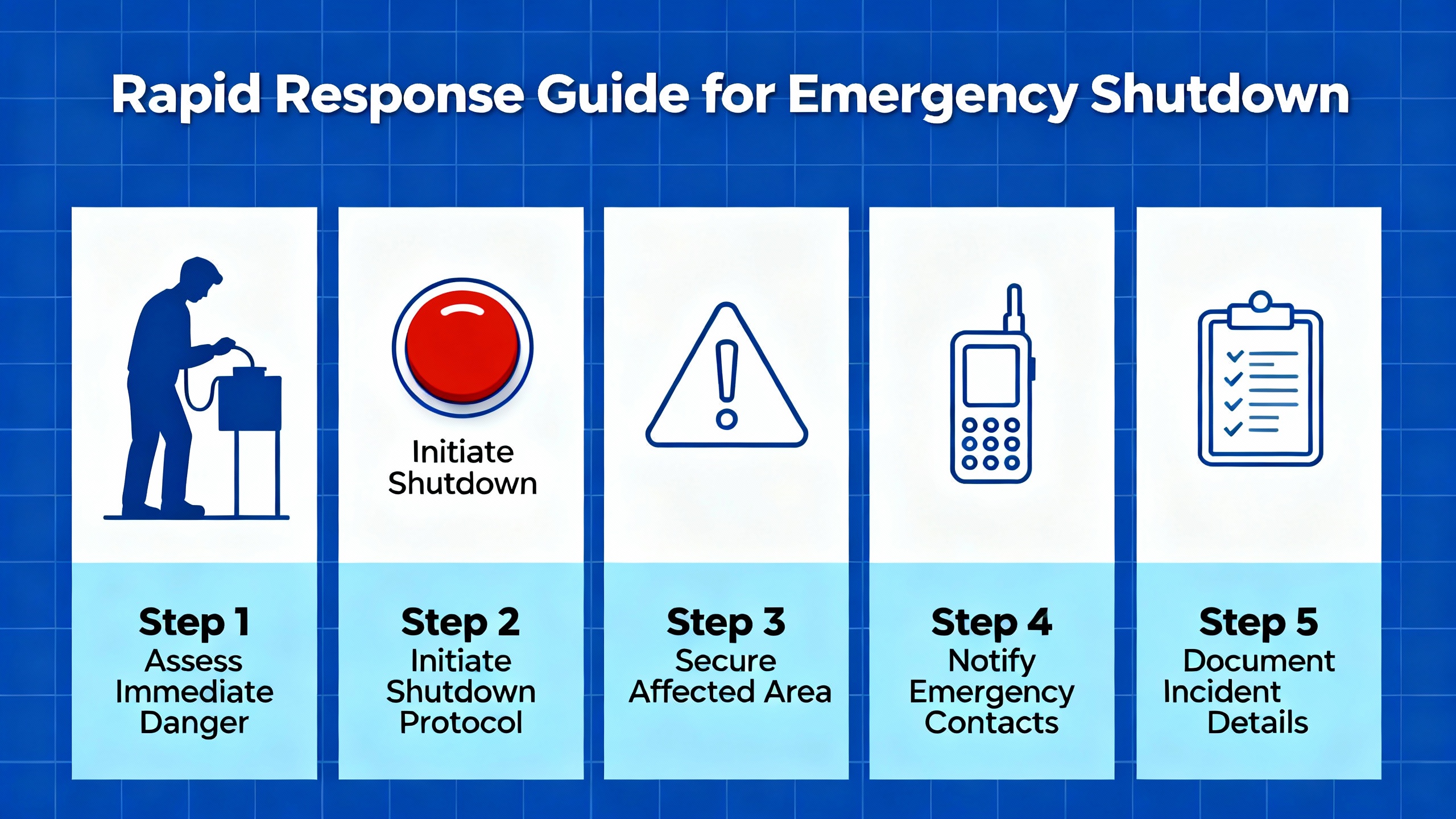

Even with the best preventive program, you will eventually face situations where an emergency shutdown is the right decision. The way you respond in those minutes and hours determines whether you simply lose production or also create secondary incidents, injuries, or long-term damage.

AlltraconŌĆÖs emergency shutdown guidance, SafexŌĆÖs safe shutdown and startup practices, OSHA emergency response training, and Vector SolutionsŌĆÖ safety recommendations align on several key points. First, immediate actions must protect personnel. That includes clear evacuation procedures, reliable alarm and communication systems, and predefined roles so that no time is wasted deciding who does what. Alltracon stresses that fast, decisive response limits escalation and reduces both operational and financial impacts.

Second, emergency protocols should be built on risk assessment done in advance. Identifying critical systems, hazardous inventories, and likely failure modes beforehand allows the plant to prepare targeted contingency plans and containment measures. In practice, that may mean pre-defined emergency shutdown sequences in the control system for specific units, pre-positioned barriers or isolation devices for hazardous materials, and trained response teams for tasks like leak isolation or fire response.

Third, real-time data matter during an emergency. Alltracon highlights data logging and real-time monitoring of parameters like temperature, pressure, and flow as tools for early detection and informed decision-making. In a modern plant, that translates into making sure your historian, alarm management system, and critical instrumentation remain reliable during abnormal events and that operators are trained to interpret the information under stress, not just during normal operation.

Fourth, documentation and communication have to keep up with the pace of the event. Safex recommends continuous communication through shutdown, startup, and post-event evaluation. OSHA emergency training materials and campus emergency programs, such as those described by Fort Lewis College, stress that most employees are not emergency responders; their role is to raise the alarm, evacuate safely, and follow established procedures, not to improvise their own response. That distinction should be reflected in training and in what you expect people to do when alarms go off.

Finally, post-event review is non-negotiable. Alltracon, Quality Millwright, Plant Engineering, and several other sources emphasize after-action reviews, root-cause analysis, and lessons-learned sessions. In the context of emergency shutdowns, that means looking not only at the immediate technical trigger but also at communication performance, adherence to procedures, human factors, and any gaps in the safety or maintenance programs that allowed the situation to develop.

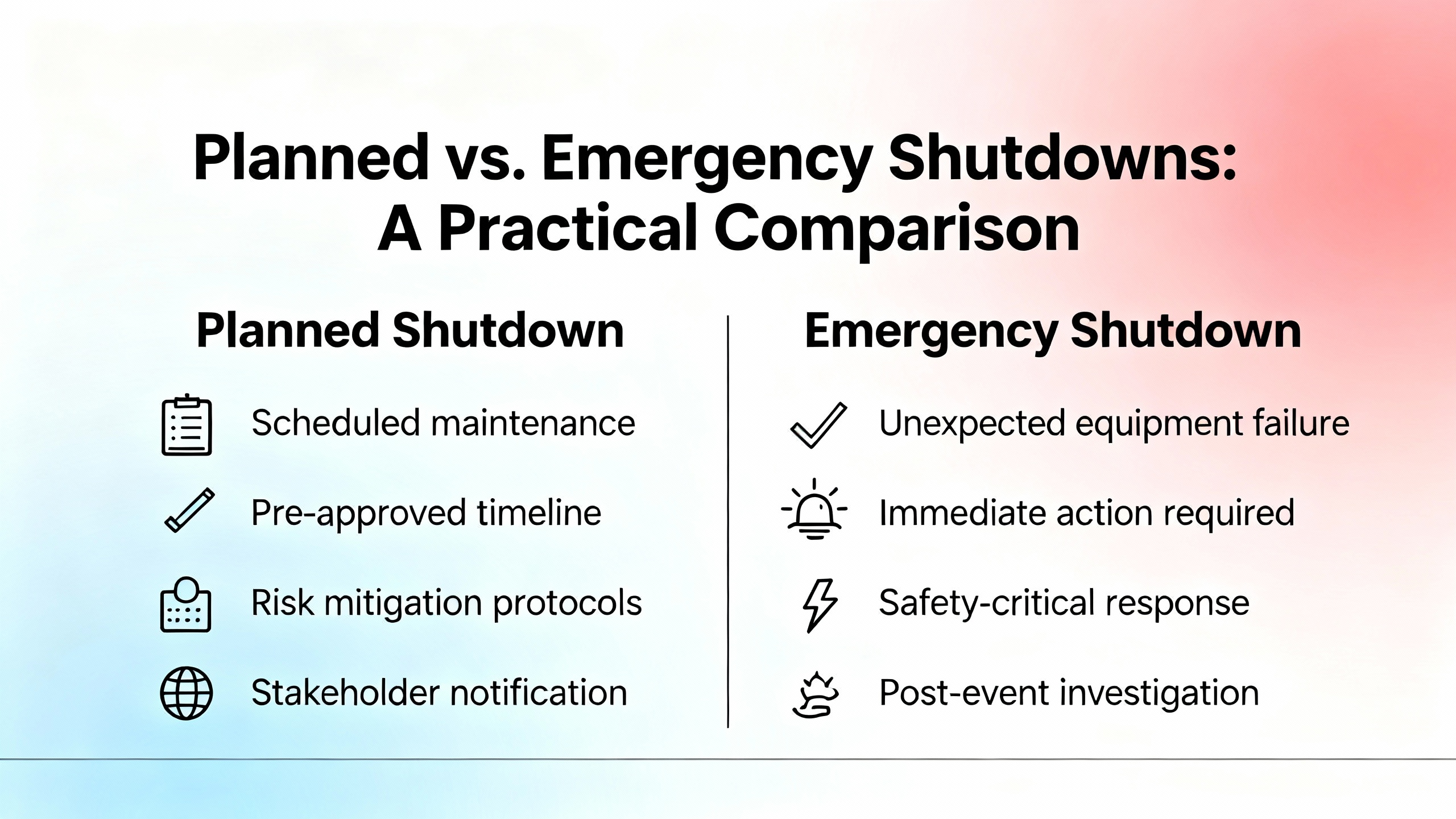

The differences between planned and emergency shutdowns show up clearly when you compare them side by side. Drawing on work from Fess Group, Alltracon, Bolton Holdings, Quality Millwright, and others, the following table summarizes the contrast.

| Dimension | Planned shutdown / turnaround | Emergency shutdown |

|---|---|---|

| Trigger | Scheduled maintenance, inspection, or upgrade | Unexpected failure, safety breach, or external event |

| Control of timing | Organization chooses timing and duration | Event dictates timing; action must be immediate |

| Primary objective | Optimize maintenance, upgrades, and regulatory compliance | Protect life, environment, and equipment from escalating hazards |

| Planning horizon | Months to over a year, depending on scope | Minutes to hours, based on pre-defined emergency procedures |

| Cost profile | Predictable with contingencies; lower unit cost of work | High, including overtime, rush parts, and lost production |

| Risk profile | Managed via detailed planning, permits, and training | High; relies on robustness of safety systems and emergency planning |

The goal of proactive maintenance and strong safety culture is to keep as much work as possible on the left side of that table, while making sure that when you do land on the right side, your emergency systems and people are ready.

Technology and procedures are necessary but not sufficient. The underlying safety and reliability culture determines how they are used in practice.

Vector Solutions notes that nearly two out of five industrial workers report safety being discussed only after incidents, which is a strong signal that many organizations remain in a reactive posture. The same article describes safety culture maturity using the DuPont Bradley Curve, where the most advanced, interdependent cultures are those in which employees look out for each other and feel safe reporting hazards without retaliation.

Tool4pro, Safex, and Alltracon all emphasize systematic training and communication as levers for improving this culture. This includes site-specific safety orientation for employees and contractors, training on work permits and LOTO, clear communication of shutdown and startup procedures, and regular drills and briefings. OSHA emergency training guidance supports annual refresher training and scenario-specific drills, especially where hazardous materials are present.

Plant Engineering and Reliable Plant connect culture directly to reliability. They recommend cross-functional teams, regular feedback sessions, and involving operators and maintainers in design and decision-making. When operators are encouraged to report abnormal conditions early and participate in root-cause analysis, the plant discovers problems before they become emergencies. When maintenance technicians are given the time and support to document as-found and as-left conditions, procedures improve instead of repeating the same fixes.

From a controls and automation standpoint, one sign of a healthy culture is how people treat alarms and interlocks. In a strong culture, there is low tolerance for nuisance alarms, documented processes for addressing them, and serious scrutiny before any safeguard is bypassed. In a weak culture, alarms are silenced, emergency stops are treated as convenient stop buttons, and temporary overrides become permanent. Those patterns are precursors to emergency shutdowns, and they are cultural issues as much as technical ones.

In practical terms, preventing emergency shutdowns and improving rapid response means aligning several streams of work.

At the plant level, leadership has to treat maintenance shutdowns as strategic projects with sufficient lead time, realistic budgets, and clear scope, as advised by Alltracon, BES Group, BLJ In-situ Solutions, TriMedia, Quality Millwright, and others. Reliability tools and predictive technologies recommended by Plant Engineering and Reliable Plant should be integrated into daily operations, not treated as optional extras.

At the safety level, shutdown and startup activities must be recognized as high-risk operations that require formal procedures, permits, and training in line with OSHA and guidance from organizations such as Safex, ProcessBarron, NMCCat, and Tool4pro. Lockout/tagout, confined-space entry, work-at-height rules, and hazardous-materials controls all need to be consistently applied, documented, and audited.

At the automation and controls level, emergency stop devices and shutdown logic have to be designed, installed, and tested as critical safety components, in the spirit of the EŌĆæstop practices described by EŌĆæSwitch and the emergency protocols outlined by Alltracon. Historians, alarm systems, and real-time monitoring should be configured to support early detection, clear diagnostics, and effective decision-making before, during, and after abnormal events.

And at the cultural level, managers, engineers, and front-line workers have to move from a mindset of ŌĆ£getting through the outageŌĆØ to one of continuous learning. Post-shutdown evaluations, near-miss reviews, and cross-functional debriefs, as recommended by many of the cited sources, should be used not just to close paperwork but to drive specific improvements in procedures, training, and design.

When these pieces come together, the plant spends more time in controlled, planned shutdowns and far less in panicked emergency stops. And when an emergency does hit, the response is faster, safer, and more effective, because the same discipline used for proactive maintenance is already built into how people think and how systems are designed.

In the field, that is what success looks like: not a world without shutdowns, but a plant where shutdowns are expected, prepared for, and used to strengthen the system rather than expose its weaknesses.

Leave Your Comment