-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When you are standing in front of a silent conveyor or a dead filler on the night shift, the theory of ŌĆ£Industry 4.0ŌĆØ suddenly matters much less than one simple question: how fast can we get the right part and get this line running again. As an automation engineer who has spent plenty of early mornings staring at failed drives and black HMI screens, I can tell you that your choice of rapid response automation parts supplier often determines whether you lose a few hours or an entire week of production.

This article walks through how rapid response parts partners actually work, which components most often trigger emergency calls, and how to design a spare-parts strategy that blends onŌĆæsite inventory with trusted external suppliers. The focus is pragmatic: decisions you can make today so you are not scrambling when the next failure hits.

Unplanned downtime has always eroded revenue, customer satisfaction, and production goals. What has changed in the past few years is the leadŌĆætime picture. Industrial Automation Co. has documented how supply chain instability, tariffs, and vendor shortages turned some drive replacements from roughly two days in 2019 into eight weeks or more, especially for legacy or tradeŌĆærestricted products. In that environment, simply ŌĆ£ordering from the OEM and waitingŌĆØ is no longer a safe fallback for critical assets.

At the same time, the complexity and interdependence of modern control architectures have increased. A failed variable frequency drive can halt every conveyor on a line. A dead HMI can make a system unusable even when the PLC and drives are perfectly healthy. A single 24 VDC power supply or I/O module can bring an entire packaging cell down. The blog on emergency spare parts from Industrial Automation Co. makes this clear: many of the failures that cause total line stoppages are neither exotic nor easily bypassed.

Platforms in adjacent domains, such as EverbridgeŌĆÖs criticalŌĆæevent management solutions, emphasize that ŌĆ£speed mattersŌĆØ and promote oneŌĆæclick automated alert workflows. That same mindset applies to industrial automation parts: when a critical component fails, your response speed and the quality of your playbook determine whether you are managing a minor incident or a fullŌĆæscale crisis.

A rapid response parts supplier is not just an online catalog with overnight shipping. Done right, it is a hybrid of stocked inventory, expert technical support, and logistics discipline, all focused on minimizing your downtime.

Industrial Automation Co. positions its emergency replacement service explicitly as an alternative to long OEM lead times. For orders placed by 3:00 PM Eastern, they offer sameŌĆæday shipping, with typical delivery windows of twentyŌĆæfour to fortyŌĆæeight hours. Every emergency replacement ships with a twoŌĆæyear warranty and free technical support before and after the sale. Their case studies include a food processor in North Carolina avoiding about $50,000 in lost product by getting an overnight Siemens drive replacement, a Midwest automotive plant clearing a failed AllenŌĆæBradley PLC stoppage in under thirtyŌĆæsix hours, and a Texas packaging facility skipping a sixŌĆæweek OEM wait for a new HMI through sameŌĆæday shipment.

ABBŌĆÖs emergency parts service shows the same pattern at a global scale. ABB maintains certified parts in stock, available in new, refurbished, and preŌĆæowned condition. Requests can be initiated online or via local ABB centers, and parts are shipped using the quickest available method from their worldwide logistics network. Critically, ABB parts experts are available around the clock, so customers are not left to decode part numbers alone while a process unit is down.

Classic Automation provides another view of this model, especially for legacy systems. They specialize in used and obsolete automation parts, with a portfolio approaching one million items from major brands such as ABB, AllenŌĆæBradley, Siemens, Mitsubishi, Omron, and others. Their refurbished parts and repairs carry a twoŌĆæyear warranty and are backed by comprehensive functional testing using hundreds of systemŌĆæspecific test fixtures. Emergency shipping is available to get production back online quickly.

Obso Automation focuses on both current and obsolete parts. They maintain their own inventory and leverage a network of brand specialists across the United States, Europe, and the United Kingdom, typically offering free global shipping. New products carry a twentyŌĆæfourŌĆæmonth warranty, and preŌĆæowned, exchange, and refurbished items come with a twelveŌĆæmonth warranty, giving plants flexibility to choose between budget and risk.

DO Supply frames its business around ŌĆ£needŌĆæitŌĆænowŌĆØ replacement parts for PLCs, drives, motors, and HMIs, emphasizing expert support, speed, and reliability. Industrial Automation Co., a veteranŌĆæowned distributor recognized by Inc. 5000 as one of the fastestŌĆægrowing U.S. companies, similarly highlights rapid response, technical expertise, and competitive pricing. Used correctly, partners like these become an extension of your maintenance strategy rather than just a place to swipe a credit card.

Rapid response is as much about expertise as it is about inventory. Industrial Automation Co. explicitly includes free technical support with its emergency replacements. ABBŌĆÖs emergency service is staffed by specialists who know their installed base. Classic Automation operates repair centers focused on restoring and testing complex electronics, not just shipping replacements.

Several service organizations take that a step further into full lifecycle support. Bastian Solutions offers preventative maintenance, replacement parts, equipment repairs, and twentyŌĆæfourŌĆæhour system support, regardless of equipment manufacturer. Their technicians are positioned as experts in material handling equipment and software like Exacta, giving customers a single support channel for mixed fleets.

ICR Services structures its offering into five integrated business units: Repair, Equipment, Robots, Service, and Engineering. That combination of maintenance, robotics, and engineering capabilities creates a fullŌĆæservice MRO partner aimed at achieving high availability and performance across robots and related equipment.

Sure Controls provides onŌĆæsite automation field service along with industrial distribution, engineering, integration, repair, and training, explicitly aiming to ŌĆ£empower worldŌĆæclass manufacturingŌĆØ through automation solutions. Sherman Industries focuses on robot services and integration for brands such as Fanuc, ABB, Yaskawa, and KUKA, from new system integration to maintenance and troubleshooting of legacy robots.

RAM Solutions, a nationwide automation parts distributor serving the United States and Mexico, emphasizes product specialization and solutionŌĆæoriented support. Their emergency response service is available during business hours, Monday through Friday from 8:00 AM to 6:00 PM, which can be acceptable for some plants but risky for facilities that run continuous operations on weekends.

Taken together, these examples highlight an important point: you are not only choosing who ships hardware. You are choosing who answers the phone at 2:00 AM, who helps you crossŌĆæreference a discontinued servo drive, and who can support you later with repairs, training, and system upgrades.

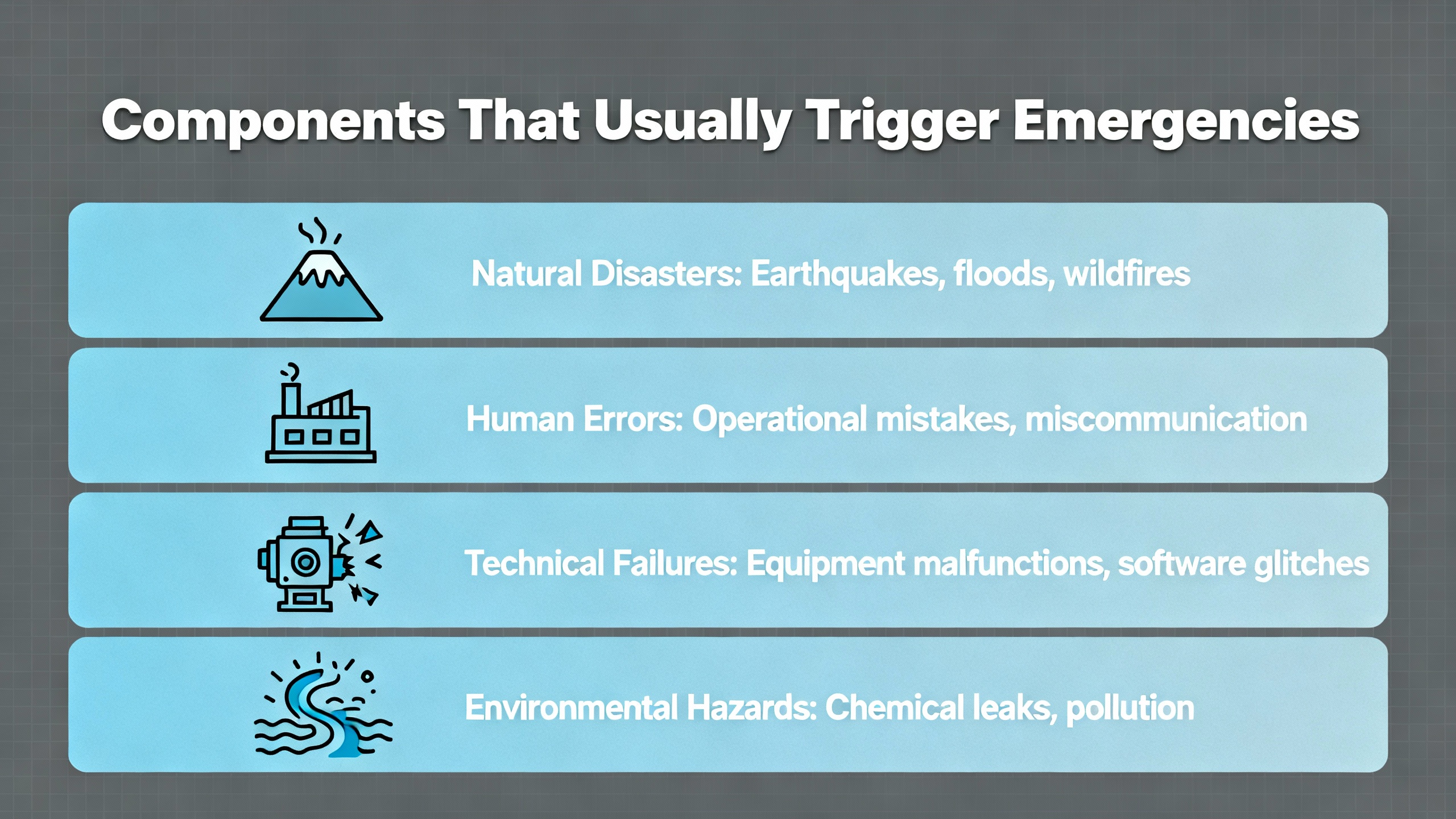

Some component failures are annoyances. Others stop your plant outright. The Industrial Automation Co. guidance on emergency spares identifies a set of categories that, in practice, account for many of the ŌĆ£line downŌĆØ calls.

Variable frequency drives sit near the top of that list. VFDs regulate motor speed and torque for assets such as conveyors, pumps, and chillers. When a main conveyor drive fails, it is common for the entire line to stop. Modern drives also frequently integrate tightly with upstream PLC logic and safety interlocks. That combination of process criticality and configuration complexity makes compatible spare drives a highŌĆævalue item. The article specifically mentions popular families such as AllenŌĆæBradley PowerFlex 525 and 70, Siemens Micromaster and G120, WEG CFW, and Schneider Altivar 320 and 630 as examples of drives plants often standardize on.

Servo drives and motion amplifiers are just as critical in highŌĆæprecision applications. These devices provide accurate motion control for CNC machines, robotics, and indexing systems, and they generally cannot be overridden safely by manual controls. When a servo axis fails on a pickŌĆæandŌĆæplace robot or a rotary indexer, production usually stops immediately. The Industrial Automation Co. article points to Mitsubishi MRŌĆæJ2S and J2, Yaskawa SGDH, SGDB, and SGDV, and FANUC A06B drives as examples of families where keeping compatible spares on hand can make the difference between a quick swap and an extended outage.

HumanŌĆæmachine interfaces are another common single point of failure. HMIs and operator panels are the main way operators visualize and control automated systems. A plant can have perfectly fine PLCs and drives, but if the HMI touchscreen has burned out or a power surge has destroyed its electronics, operators are effectively blind. Failures of AllenŌĆæBradley PanelView Plus, Mitsubishi GOT2000 panels, or Siemens TP and KTP series panels are typical triggers for emergency calls, and stocking at least one compatible spare for critical stations is often justified.

Underpinning all of this are power supplies and PLC modules. Loss of 24 VDC control power due to a failed power supply, or a single faulty I/O module on a critical rack, is a frequent cause of shutŌĆædowns. The Industrial Automation Co. article recommends keeping spare 24 VDC power supplies and key I/O modules, such as AllenŌĆæBradley 1769 series and Siemens S7ŌĆæ1200 digital and analog modules, because they are inexpensive compared with the cost of downtime and are relatively easy to swap.

Finally, communication modules and cables form the data backbone between drives, PLCs, and SCADA. A failed EtherNet/IP adapter like the 22ŌĆæCOMMŌĆæE module on a PowerFlex drive, a damaged Profinet or Profibus connector, or a faulty serial cable or USBŌĆætoŌĆæRS232 adapter can silently cripple a system. The article highlights these less glamorous components because you cannot always ŌĆ£seeŌĆØ their failure at a glance, yet they can stop data exchange just as effectively as a failed drive.

Classic AutomationŌĆÖs catalog and repair capabilities reinforce how broad this landscape is. They support PLCs, drives, panel controllers, and other equipment across major manufacturers, with particular strength in systems that are no longer current from the OEM. Obso AutomationŌĆÖs focus on active and obsolete parts shows the same reality: legacy hardware does not disappear from the plant floor simply because it disappears from the OEM price list.

Even the best rapid response supplier cannot fully compensate for poor spareŌĆæparts strategy inside the plant. There is a practical balance between keeping everything on the shelf and relying entirely on external partners.

Industrial Automation Co. recommends starting with your top ten downtime risks rather than attempting to inventory every possible part. In practice, that means identifying which components your line depends on the most, estimating the cost of downtime for each, and looking at replacement lead times. Once you understand which failures would cost you the most and take the longest to recover from, you can decide which parts should be stocked onŌĆæsite and which you can reasonably rely on a twentyŌĆæfour to fortyŌĆæeight hour shipment for.

For example, if a variable frequency drive controls a bottleneck conveyor that stops your entire plant when it fails, and if the OEM replacement carries an eightŌĆæweek lead time, keeping a compatible spare on the shelf is usually a straightforward decision. On the other hand, a nonŌĆæcritical VFD on an auxiliary pump with low downtime cost might be a good candidate to source from a rapid response supplier on demand.

The same logic applies to PLC racks, HMIs, and communication modules. HighŌĆæimpact, longŌĆæleadŌĆætime components justify onŌĆæsite spares, especially when configuration transfer is complex. LowerŌĆæimpact or more readily available components can often be left to your emergency partner, provided that partner has proven inventory depth and shipping speed for those items.

In my experience, a hybrid approach works best. You define a minimal but deliberate core of onŌĆæsite spares based on risk and then lean on one or two vetted rapid response suppliers for everything else. That way you are not tying up unnecessary capital in shelves of rarely used parts, but you are also not trusting your plantŌĆÖs survival entirely to someone elseŌĆÖs warehouse.

Not every organization that can help in an emergency does the same thing. It is useful to distinguish between OEM emergency services, independent parts distributors, repairŌĆæcentric providers, and fullŌĆæservice MRO partners.

OEMs and OEMŌĆærun emergency services, such as ABBŌĆÖs 24/7 emergency parts program, usually offer the strongest assurance of compatibility and upŌĆætoŌĆædate firmware for their own equipment. They maintain certified parts and often have global logistics networks. The tradeoff, as highlighted by Industrial Automation Co., is that standard OEM channels can have long lead times, particularly for drives and legacy components under supply constraints. Emergency programs mitigate this, but not every OEM maintains deep stocks of older gear.

Independent distributors such as Industrial Automation Co., DO Supply, Classic Automation, and Obso Automation can provide multiŌĆæbrand coverage, focusing on speed and inventory depth across vendors. Classic Automation emphasizes its nearly one millionŌĆæpart inventory and twoŌĆæyear warranty on refurbished parts and repairs. Obso Automation supplements its own stock with a network of specialist partners across regions and gives explicit warranty terms of twentyŌĆæfour months for new and twelve months for preŌĆæowned and refurbished products. These companies are often the ones that can ship something compatible tonight when OEMs quote weeks.

RepairŌĆæcentric providers, exemplified by Classic AutomationŌĆÖs repair services, focus on restoring failed modules to service. Their process centers on functional testing using systemŌĆæspecific fixtures, and they stand behind repairs with the same twoŌĆæyear warranty they apply to refurbished parts. This is especially valuable for expensive or highly specialized modules where new units are unavailable or excessively costly.

FullŌĆæservice MRO partners such as ICR Services, Bastian Solutions, Sure Controls, and Sherman Industries layer engineering, integration, and field service on top of parts and repairs. They help design and maintain automation systems, provide onŌĆæsite troubleshooting, and support upgrades over time. In practice, that means when a robot fails or a conveyor system underperforms, they can address both the component and the systemŌĆælevel issues.

The right mix for your plant might include all of these. An ABB emergency service contract might cover critical process control hardware, while an independent distributor handles multiŌĆæbrand drives and HMIs, a repair provider restores obsolete modules, and an MRO partner supports robots and material handling systems.

| Partner Type | Typical Strengths | Typical Limitations |

|---|---|---|

| OEM emergency parts services | Certified parts, tight integration with installed base, strong brand alignment | Standard channels can have long lead times, limited legacy coverage |

| Independent parts distributors | MultiŌĆæbrand inventory, fast shipping, competitive pricing, flexible sourcing | Less involved in systemŌĆælevel engineering and longŌĆæterm design decisions |

| Repair and refurbish providers | Extend life of obsolete or costly parts, rigorous testing, warranty on repairs | Repair lead times may not solve immediate ŌĆ£line downŌĆØ events alone |

| FullŌĆæservice MRO and integrators | Combine parts with engineering, field service, training, and lifecycle support | May rely on external distributors for certain brands or rare spares |

This table is not about choosing one column. It is about understanding which partners you already have and where you have gaps. The emergency supplier that can ship a drive in twentyŌĆæfour hours is not necessarily the same one that should be reprogramming your robot or redesigning your HMI screens.

When you are buying under pressure, it is tempting to treat the part as a commodity. That is a mistake. The way a supplier handles testing, warranty, and support is one of the clearest indicators of how much risk you are taking on.

Classic AutomationŌĆÖs approach to repairs is instructive. They build systemŌĆæspecific test fixtures and perform comprehensive functional testing tailored to each product line. Every refurbished part and every repair is backed by a twoŌĆæyear warranty. That combination of targeted testing and long warranty is not an accident; it is a signal that they expect the part to perform in a production environment.

Obso Automation similarly defines clear warranty terms: twentyŌĆæfour months for new products and twelve months for preŌĆæowned, exchange, and refurbished items. Industrial Automation Co. extends a twoŌĆæyear warranty on its emergency replacement parts. These are objective commitments you can compare across suppliers rather than relying solely on marketing language.

Data about customer behavior can also be a rough signal. Industrial Automation Co. cites tens of thousands of monthly site visitors and thousands of inŌĆæstock parts. A company named among the fastestŌĆægrowing businesses in the country by Inc. 5000 has at least demonstrated significant market traction. Classic AutomationŌĆÖs more than twenty years in business and nearly one million supported parts likewise point to sustained demand.

On the process side, ABB emphasizes standardized processes, tools, and metrics across its global parts logistics and repair centers. That kind of standardization is what allows them to promise fast and reliable delivery anywhere in the world. When you evaluate suppliers, ask direct questions about how they test, how they handle returns, and how they track defects. An emergency replacement is only a solution if it works when you install it.

Having a rapid response supplier in your contact list is only half the job. The other half is designing a repeatable response process inside your plant so you are not improvising under stress.

The emergency spares article from Industrial Automation Co. effectively recommends building a riskŌĆæbased view of your equipment and keeping emergency spares for the top downtime drivers. In practice, when a failure occurs, maintenance and controls engineers should already know which components are ŌĆ£no debateŌĆØ swap candidates and whether the spare sits in your stockroom or must be sourced externally.

Borrow a page from the criticalŌĆæevent world. Everbridge describes oneŌĆæclick alert management that drives a complete response workflow. On the plant floor, your equivalent can be a simple, structured playbook: confirm the diagnosis, capture the part number and any configuration details, check onŌĆæsite spares, and, if needed, escalate immediately to your chosen emergency parts partner with a clear description of the failure and the required part. The faster and more consistently you do this, the more you benefit from the supplierŌĆÖs ability to ship in twentyŌĆæfour to fortyŌĆæeight hours.

If you work with fieldŌĆæserviceŌĆæcapable partners such as Bastian Solutions, Sure Controls, or Sherman Industries, decide in advance which types of incidents justify calling them onŌĆæsite. A failed robot axis on a complex multiŌĆærobot cell may be far better handled by a specialist who lives and breathes that brand than by inŌĆæhouse technicians learning on the fly during a crisis.

Finally, respect the limits of each partnerŌĆÖs availability. RAM Solutions, for example, clearly states businessŌĆæhour availability and closure on weekends. If your plant runs continuous operations through weekends and holidays, that may be a gap you need to fill with another partner that offers true 24/7 coverage.

In many cases, yes. The Industrial Automation Co. case where a food processor avoided about $50,000 in lost product due to an overnight drive replacement illustrates how quickly downtime costs dwarf any premium on the part. When OEM lead times stretch into weeks, the economics usually favor a rapid response supplier for critical components. For nonŌĆæcritical equipment or planned upgrades, standard OEM channels can still make sense.

Refurbished and preŌĆæowned parts can be a solid option when they are backed by rigorous testing and meaningful warranties. Classic AutomationŌĆÖs twoŌĆæyear warranty on refurbished parts and repairs, combined with systemŌĆæspecific functional testing, and Obso AutomationŌĆÖs twelveŌĆæmonth warranty on preŌĆæowned and refurbished items are good examples of how reputable suppliers reduce risk. The key is to differentiate between vendors that simply resell used gear and those that treat refurbishment and testing as an engineering discipline.

There is no universal number, but the approach is clear. Follow Industrial Automation Co.ŌĆÖs recommendation to focus on your top downtime risks rather than trying to stock everything. Identify which components your lines depend on most, estimate the cost of downtime for each, and factor in replacement lead times. HighŌĆæimpact, longŌĆæleadŌĆætime items typically belong on your shelf. LowerŌĆæimpact parts or those that your rapid response supplier can reliably ship in a day or two can often be left in their warehouse instead of yours.

In the end, rapid response automation parts suppliers are not just vendors; they are part of your resilience strategy. When you treat them as true emergency partners, align your spareŌĆæparts strategy with their capabilities, and rehearse your response process before something fails, you give your plant a much better chance of turning future ŌĆ£line downŌĆØ moments into short, controlled interruptions rather than painful, openŌĆæended crises.

Leave Your Comment