-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Industrial buyers rarely get in trouble for shortlisting Schneider Electric. It is a global brand, present in most regions, with solutions that run from the incoming utility breaker all the way down to the PLC and HMI. But in real plants, data centers, and utilities, Schneider is never the only viable option. You will be comparing it against Siemens, ABB, Rockwell, Eaton, Honeywell, Vertiv, Panduit, Hitachi Energy, and many more.

This article walks through that comparison from the perspective of an industrial automation engineer who spends a lot of time in switchgear rooms and control panels, not just in conference rooms. I will lean on published research from sources such as Marketing91, ABI Research, Gartner, and a range of supplier-evaluation guides, then translate that into practical, on-site decision advice.

The goal is simple: if you are deciding whether to go with Schneider Electric or one of its competitors for a new plant, a major upgrade, or grid modernization, you should finish this article with a clear short list and a structured way to defend your choice.

Marketing91 describes Schneider Electric as a France-based global leader in energy management, automation, and sustainability solutions with more than 180 years of history and operations in over 100 countries. Its portfolio covers electrical distribution, automation and control, energy management, and data center solutions, serving residential, commercial, industrial, and infrastructure customers. Across that range, its positioning centers on energy efficiency, reduced greenhouse-gas emissions, and operational performance.

ABI Research evaluated vendors in energy grid digitalization technologies and ranked Schneider Electric as the overall leader, ahead of Siemens AG and GE Vernova. That ranking is based on innovation and implementation across advanced distribution management systems, distributed energy resource management systems, energy management systems, outage management, and related grid software, plus the strength of their ecosystems, cybersecurity posture, and sustainability orientation.

For industrial buyers, the practical takeaway is that Schneider Electric is not just a breaker and PLC vendor. It is one of a small group of companies that can credibly offer end-to-end electrification and digitalization across plant, building, and grid, combining hardware, automation, and software.

Marketing91ŌĆÖs review of Schneider ElectricŌĆÖs market shows that its competitors fall into distinct groups rather than being one long, interchangeable list. Thinking in these groups is helpful when you are building a vendor strategy.

| Segment | Examples cited in research | Typical competitive focus relative to Schneider Electric |

|---|---|---|

| Diversified industrial and power conglomerates | Siemens, ABB, General Electric, Mitsubishi Electric, Hitachi, Toshiba, Siemens Energy, GE Vernova | Broad electrical engineering, power systems, industrial automation, smart grid, and energy management across many sectors |

| Industrial automation specialists | Rockwell Automation, Omron, Bosch Rexroth, Yokogawa, Festo, SMC Corporation, WEG | Factory and process automation, motion control, robotics, sensing, directly challenging in PLCs, drives, control, and Industry 4.0 |

| Building and HVAC focused | Johnson Controls, Honeywell International, Legrand, Danfoss | HVAC, building automation, fire and security, lighting, and electrical building infrastructure |

| Power and energy management | Eaton, Hitachi, Toshiba, WEG, plus parts of Siemens and ABB portfolios | Power distribution, backup power, grid solutions, renewable integration, power quality |

| Data center and digital infrastructure | Vertiv, BASELAYER, Panduit, GE Digital, Dassault Systemes, Phoenix Contact | Data center power and cooling, modular prefabricated data centers, cable and network infrastructure, industrial software and analytics |

ABI Research adds another layer for grid-focused buyers. In its competitive ranking of grid digitalization technologies, it classifies Schneider Electric, Siemens AG, and GE Vernova as market leaders, Hitachi Energy and ABB as mainstream, and Mitsubishi Electric Power Products and Honeywell as followers. Hitachi Energy is highlighted for notable innovation, including a dedicated AI solution for grid applications called Nostradamus AI and advanced wildlife management that interacts with grid operations.

For data center infrastructure management tools, GartnerŌĆÖs reviews describe Schneider Electric as one vendor in a larger DCIM field and highlight PanduitŌĆÖs SmartZone DCIM as a strong alternative, particularly for equipment lifecycle visibility, power usage tracking, and energy savings.

The point is that you are rarely choosing between Schneider Electric and a generic ŌĆ£Other.ŌĆØ You are choosing between Schneider and one or more specific segments: another global conglomerate, a focused automation specialist, a building-automation heavyweight, a power-management specialist, or a data center or software-centric player.

If you are a utility, an industrial campus with your own substation, or a large institutional facility with heavy grid interaction, the ABI Research study is especially relevant.

Schneider Electric ranks first in ABI ResearchŌĆÖs grid digitalization competitive analysis due to its innovation in advanced distribution management, distributed resource management, outage management, energy and flexibility trading, virtual substations, and cybersecurity combined with a strong ecosystem and broad market presence. Siemens AG and GE Vernova are close behind, also categorized as market leaders. Hitachi Energy and ABB are identified as mainstream vendors, with Hitachi Energy gaining attention for Nostradamus AI, which is described as a dedicated AI solution for grid applications and for its innovations in wildlife management tied to grid operations. Mitsubishi Electric Power Products and Honeywell are identified as followers, with Mitsubishi noted for novel substation monitoring.

ABI ResearchŌĆÖs core recommendation is that transmission and distribution operators get most value from vendors offering a full range of high-quality, tightly integrated software and hardware solutions, not piecemeal tools. That is consistent with what most of us see on site: if your control room, field devices, cybersecurity, and analytics are stitched together from one-off subsystems, the integration and maintenance overhead often eats any initial savings.

From a practical buying standpoint, if your main challenge is managing growing capacity constraints, high penetration of renewables, and complex grid operations, it makes sense to have at least Schneider Electric, Siemens AG, and GE Vernova on the long list. Hitachi Energy and ABB also deserve serious consideration when you are emphasizing innovation in specific grid functions or when you are balancing existing installed base, especially if Nostradamus AI and related solutions align with your roadmap.

In selection workshops, I like to map each vendorŌĆÖs strengths onto your specific grid problems. If your pain is congestion caused by intermittent renewables, you should push vendors to demonstrate not just generic ADMS features but actual capabilities for forecasting and flexibility management. ABI ResearchŌĆÖs work gives you one external benchmark, but the plant or grid-specific demo is what will decide who is really ahead for your use case.

Marketing91 groups a number of vendors as industrial automation specialists, including Rockwell Automation, Omron, Bosch Rexroth, Yokogawa, Festo, SMC Corporation, and WEG. These companies focus on factory and process automation, motion control, robotics, and sensing technologies, and they directly challenge Schneider Electric in PLCs, drives, control systems, and Industry 4.0 solutions.

Schneider ElectricŌĆÖs strength here is that its automation portfolio fits into a much broader electrification and energy-management stack. In one vendor you can get low-voltage and medium-voltage distribution, motor control centers, drives, PLCs, safety, and often the supervisory software. That can simplify design, procurement, and spare parts.

By contrast, the automation specialists cited in Marketing91ŌĆÖs analysis lean very heavily into controls, motion, and field devices. For a buyer, that often shows up as more depth in specific automation technologies and strong ecosystems of machine builders and system integrators that revolve around those platforms.

The trade-off is usually not about brand so much as about system boundaries. If you want a fully integrated electrical and automation package, staying with Schneider Electric or another large conglomerate is often the easiest way to manage risk. If you want to optimize around controls and motion first, and you are comfortable coordinating with multiple suppliers for switchgear and power distribution, the automation specialists can be attractive.

In brownfield upgrades where your existing installed base is skewed toward a particular automation ecosystem, the safest move is usually to extend that ecosystem rather than forcing a large-scale migration to another vendor, unless there is a very clear life cycle or support problem. Supplier evaluation work from sources such as ElectronicComponent.com and Pro QC consistently warns that chasing the lowest price or a shiny new platform without accounting for integration, retraining, and spare-part continuity can create higher total cost of ownership than sticking with the incumbent platform.

On the building side, Marketing91 identifies Johnson Controls, Honeywell International, Legrand, and Danfoss as key competitors to Schneider Electric. These vendors emphasize HVAC systems, fire and security, building automation, lighting management, and electrical building infrastructure. Schneider Electric competes here with building management systems, room controllers, smart panels, and connected wiring devices, again integrated with its energy and automation stack.

If you are responsible for a hospital, university campus, or government facility, the article from Dominion Electric on large institutions is a useful reminder of the requirements. Large institutions need robust, scalable electrical systems designed for high energy consumption, long wiring runs, and complex operations. They emphasize reliability and redundancy to prevent disruptions, especially in critical facilities like hospitals. Energy efficiency is a central design goal, with LED lighting, high-efficiency transformers, and smart control systems reducing energy use and supporting sustainability goals. Advanced technologies such as smart grids, real-time energy monitoring, and IoT-enabled components are highlighted as tools to manage demand and enable proactive maintenance.

Those requirements are broad enough that multiple vendors can meet them. In practice, buyers in this segment often evaluate Schneider Electric, Johnson Controls, Honeywell, and others based on existing installed base, the maturity of building management software, cybersecurity posture for connected buildings, and the ability to support long-term energy efficiency programs.

One practical caution from articles on choosing electrical suppliers such as those from Bless Rise and Tosunlux is to avoid selecting a building-system vendor purely on brand reputation or catalog breadth. They emphasize verification of compliance with standards such as the National Electrical Code, NFPA 70E, OSHA rules, and certification regimes like UL and IEC, along with transparent evidence of product quality and appropriate warranties. That applies equally to building-automation equipment as it does to breakers and switchgear.

In data centers and critical IT infrastructure, Marketing91 lists Vertiv, BASELAYER, and Panduit as notable competitors. Schneider Electric plays here with power distribution, UPS systems, cooling, and data center infrastructure management (DCIM) tools.

GartnerŌĆÖs review of alternatives to Schneider Electric in the DCIM tools market gives a concrete example of how a competitor positions itself. PanduitŌĆÖs SmartZone DCIM is highlighted as a solution that gives users more control and visibility into data center operations. It enables organizations to understand the end-of-life status of equipment, supports lifecycle and refresh planning, and allows quick retrieval of asset ownership length, power consumption, and equipment location. In the implementation Gartner describes, strong support from the Panduit representative throughout installation is singled out as a success factor, and the deployment reportedly led to reductions in cooling costs and overall energy savings.

For an industrial buyer with a significant data center component, the comparison is less about whether Schneider Electric or Panduit or Vertiv is ŌĆ£betterŌĆØ and more about which vendorŌĆÖs stack aligns with your operating model. If your data centers are tightly coupled to factory operations or building systems, a vendor that can integrate DCIM with plant energy management and automation may be advantageous. If you treat the data center as its own domain with its own operations team, a specialized DCIM provider may fit well even if the electrical distribution is largely Schneider-based.

The broader lesson from Gartner and other supplier-management guidance is that support and onboarding are as important as tool features. A DCIM product that looks excellent on paper but is poorly implemented will not deliver the promised cooling and energy savings.

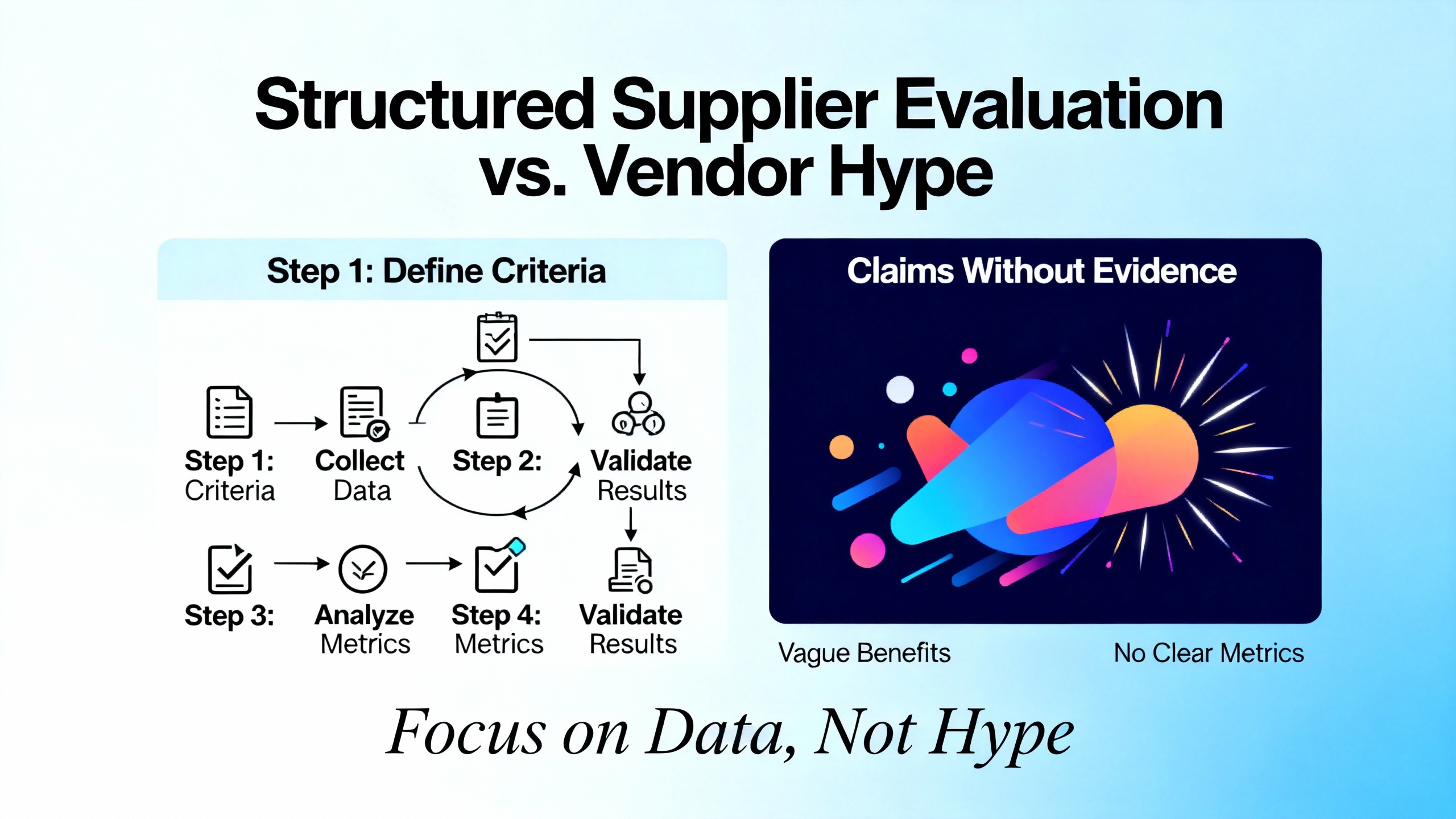

Most of the competition around Schneider Electric is between large, capable companies with overlapping portfolios and similar buzzwords. That is where a disciplined supplier evaluation process is more valuable than a list of product features.

Several of the research notes focus directly on supplier evaluation best practices. Pro QC highlights overlooked criteria such as a factoryŌĆÖs own auditing practices, incoming quality control, process monitoring, inspection record traceability, and continuous improvement culture. ElectronicComponent.com emphasizes certifications and compliance, reputation and financial stability, quality control and testing, supply chain transparency, and total cost of ownership rather than unit price. Veridion breaks supplier evaluation into steps: setting evaluation criteria, segmenting suppliers by criticality, gathering reliable data, using evaluation matrices, selecting suppliers with an eye on both scores and cultural fit, and then monitoring performance continuously. Manifestly describes supplier evaluation checklists in manufacturing and cites a mid-sized manufacturer that gained twenty percent in operational efficiency within six months by rigorously applying such a checklist.

Across these sources, a few themes apply directly when you are comparing Schneider Electric to its competitors.

First, you need clear, cross-functional criteria before you start shortlisting vendors. Production, maintenance, engineering, IT, and finance should all have a say in what matters. CarterŌĆÖs 10C or similar frameworks, mentioned in supplier-evaluation literature, are a good starting point, but you should localize the criteria to your plant. If energy efficiency and sustainability are core corporate goals, that needs to be weighted accordingly.

Second, treat vendor claims and marketing decks as hypotheses, not facts. Veridion cites a study where ninety-three percent of procurement leaders experienced adverse effects from supplier misinformation, with many facing such issues regularly. Structured data collection, independent certification checks, and sample testing are essential. ElectronicComponent.comŌĆÖs case study of NextGen Electronics shows the impact of this approach: implementing a formal vetting process with checklists, certification verification, sample testing, and performance reviews cut component failures by eighty-seven percent, raised on-time delivery from seventy-six to ninety-eight percent, eliminated supply disruptions, and increased customer satisfaction, even though component prices were around five percent higher.

Third, pay attention to lifecycle and obsolescence, especially in automation and power electronics. United Industries VA notes that seventy-three percent of industrial buyers face delays due to component shortages and that obsolete parts alone account for forty percent of production downtime. The electrical components market is projected to exceed six hundred billion dollars by 2033, and supply bases are fragmented, with sixty-eight percent of buyers using more than fifty electrical suppliers while only twenty-three percent have real-time inventory visibility. Those numbers underline why you should favor vendors and partners who can support long-term availability, recommend substitutes, and help you manage obsolescence proactively.

Fourth, consider risk from counterfeit and substandard parts. United Industries VA references ERAI data showing over one thousand fifty suspect counterfeit or nonconforming parts logged in a single year. ElectronicComponent.com similarly warns that counterfeit and substandard components can trigger recalls, legal liability, and reputation damage. This is another argument for sticking with authorized channels, vendors with strong traceability systems, and distributors that can provide solid documentation of origin and chain of custody when you are sourcing Schneider or competitor hardware.

Finally, shift your mindset from chasing the lowest line-item price to managing total cost of ownership. Simcona and other procurement guides emphasize that cheap components and platforms often lead to rework, downtime, delayed launches, and damaged customer reputation. ElectronicComponent.comŌĆÖs case study is a quantitative example of how paying a small premium for better quality and a stronger supplier can improve profitability overall.

Regardless of whether you choose Schneider Electric or a competitor, industrial power and automation systems live and die by compliance. The Bless Rise article on choosing electrical suppliers stresses the importance of alignment with NFPA codes, OSHA regulations, and especially the National Electrical Code, along with documentation such as test certificates, regulatory filings, and safety data sheets. RaivenŌĆÖs guide for electrical contractors adds the need to ensure that components are certified by a Nationally Recognized Testing Laboratory and explicitly states that suppliers should confirm NEC compliance and NRTL approval.

For components and assemblies beyond pure electrical equipment, eINDUSTRIFY underscores UL certification, IEC standards, flame resistance, and robust insulation as important safety features. ElectronicComponent.com lists key certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, AS9100 for aerospace, and RoHS or REACH compliance for restricted substances. These certifications are not marketing nice-to-haves; they are mechanisms for you to verify that the vendorŌĆÖs quality system is real.

In the context of Schneider Electric versus competitors, this means you should demand the same level of evidence and documentation from all bidders. Do not assume that a global name is automatically compliant on every product line. Make compliance verification part of your formal evaluation matrix, and ask vendors how they keep up with changing codes and standards in your jurisdictions.

Based on the research notes and on-site experience, it is more accurate to talk about pros and cons by competitor type than by individual brand.

Schneider Electric and other diversified conglomerates such as Siemens, ABB, General Electric, Mitsubishi Electric, Hitachi, and Toshiba tend to offer very broad portfolios that cover power, automation, and often digital solutions. The advantage is architectural coherence and fewer integration boundaries. For industrial buyers, that can mean easier responsibility assignment when something does not work as intended and simpler long-term support and training. The potential downside is that you are tying a lot of your critical infrastructure to a single strategic relationship, and if you do not negotiate lifecycle, pricing, and openness up front, you may face switching challenges later.

Industrial automation specialists like those identified by Marketing91 focus on automation, motion, robotics, and sensing. They may not be able to supply every breaker or panel, but they provide strong ecosystems around control and automation platforms. Their natural sweet spot is often machine-level or process-level performance, which is vital in many factories. The trade-off is that you will need a more complex supplier landscape for switchgear and power, and you will carry the integration responsibility across those boundaries.

Building and HVAC specialists such as Johnson Controls, Honeywell, Legrand, and Danfoss sit closer to the facilities side. They emphasize building automation, HVAC, fire, and lighting, and they are often trusted partners for building operators. They can compete directly with Schneider Electric in that space, but they may not bring the same depth in industrial automation. For campuses with both production and complex buildings, some buyers standardize on a single vendor for both sides; others intentionally split plant and building systems between different specialists.

Power and energy management specialists such as Eaton, Hitachi, Toshiba, and WEG compete primarily at the electrical equipment and power-systems layer, overlapping SchneiderŌĆÖs electrical distribution and energy-management offerings. Data center and digital infrastructure players like Vertiv, BASELAYER, and Panduit focus on the power and cooling of IT, along with cable and connectivity. Digital and software-centric players such as GE Digital, Dassault Systemes, and Phoenix Contact extend competition into industrial software, 3D design, digitalization platforms, analytics, and industrial communication.

Marketing91 notes that across these competitors, the recurring value propositions resemble SchneiderŌĆÖs own: high energy efficiency, sustainability, reliability, and tightly integrated hardware, controls, and digital capabilities. That is why the decision cannot be made purely on slogans. It has to be tied to the specifics of your plant and your roadmap.

When I walk a plant or a greenfield site and help a team decide between Schneider Electric and its competitors, the process usually follows a repeatable pattern that mirrors the supplier-evaluation guidance in the research.

First, I work with maintenance, operations, engineering, IT, and finance to capture non-negotiable requirements. These include safety and compliance constraints, environmental conditions, production volumes, energy-efficiency targets, cybersecurity requirements, expected life of the asset, and integration boundaries with existing systems.

Second, I look at the current installed base. If a facility already has significant Schneider Electric infrastructure and it is performing well, the burden of proof is higher for competitors that would require retraining staff, carrying a second set of spares, and changing engineering standards. That logic applies in reverse if the installed base leans toward another ecosystem.

Third, I match use cases to vendor strengths as indicated by the research. For sophisticated grid digitalization, I make sure Schneider Electric, Siemens AG, and GE Vernova are in the conversation, with Hitachi Energy and ABB as strong options depending on the focus. For factory automation dominated by motion and robotics, I consider whether an automation specialist ecosystem aligns better with the plantŌĆÖs needs even if power equipment comes from another vendor. For facilities with heavy building-automation content, I ensure that the building-focused competitors are evaluated alongside SchneiderŌĆÖs building-management offerings.

Fourth, I help the team build an evaluation matrix. Using the ideas from Veridion, Pro QC, Manifestly, and ElectronicComponent.com, we define criteria such as safety and compliance, technical fit, lifecycle and obsolescence management, digital and analytics capabilities, service and support quality, logistics and delivery performance, financial health, and total cost of ownership. We weight those criteria based on the projectŌĆÖs priorities and score each vendor based on evidence, not just presentations.

Finally, I encourage continuous monitoring rather than a one-time decision. Supplier-performance research from HUB Industrial and others emphasizes keeping track of quality, on-time delivery, service responsiveness, and cost against expectations through standardized scorecards. Given how quickly markets and technologies change, what is true about Schneider Electric and its competitors today may not hold five years from now. Regular reviews let you adjust course while protecting production.

Schneider Electric is a credible default because of its breadth, global presence, and strong position in grid digitalization according to ABI Research, but that does not automatically make it the best fit in every scenario. In some plants, a focused automation or building-automation specialist will align better with your technical needs or installed base. The safest choice is the one that meets your requirements with clear evidence and manageable lifecycle risk, not just the one with the most recognizable logo.

You should look hard at competitors when your project is heavily weighted toward one domain where a rival is particularly strong, such as grid AI at Hitachi Energy, DCIM at a specialist like Panduit, or deeply integrated motion control from an automation specialist group. You should also consider alternatives if you face lifecycle, support, or commercial issues with your incumbent vendor or if corporate strategy requires vendor diversification for risk control.

Most industrial buyers get good results by inviting a small number of serious contenders rather than many superficial bids. In practice, that often means one or two diversified conglomerates such as Schneider Electric and its closest peers, plus one or two specialists that map well to the projectŌĆÖs technical focus. What matters is not the count but the depth and objectivity of your evaluation.

In the field, nobody cares whether the gear in the electrical room is green, blue, or orange. They care that production runs, the lights stay on, safety margins are respected, and energy waste is minimized. Use the competitive intelligence from sources like Marketing91, ABI Research, and Gartner, combine it with disciplined supplier evaluation, and choose between Schneider Electric and its competitors with the same rigor you use to design a safety circuit.

Leave Your Comment